Plastic pallets have become an essential part of logistics and material handling in industries such as food processing, pharmaceuticals, and retail. However, maintaining these pallets in clean, sanitary conditions can be challenging without the right equipment. This is where a plastic pallet washer comes in. A plastic pallet washer is specifically designed to provide efficient, thorough cleaning of plastic pallets, ensuring they are free from contaminants, dirt, and bacteria.

In this blog, we’ll explore the various benefits of using a plastic pallet washer for your business and how it can improve your overall operations.

Improved Hygiene and Food Safety Standards

In industries like food processing, hygiene is not just important—it's essential. Pallets used for transporting food, beverages, or pharmaceuticals are exposed to various contaminants during their life cycle. When pallets are not properly cleaned, they can harbor bacteria, dirt, or even mold, putting your business at risk for food safety violations or cross-contamination.

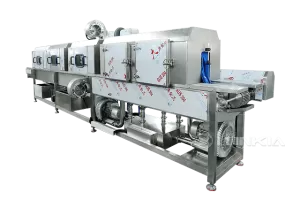

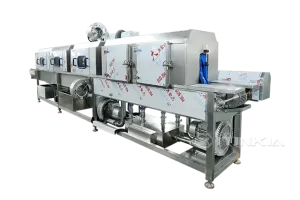

A plastic pallet washer ensures that your pallets are thoroughly cleaned and sanitized. These washers are equipped with high-pressure water jets, rotating brushes, and often a chemical sanitizing process to guarantee that pallets are not just clean but also bacteria-free. Regularly cleaning your plastic pallets with a dedicated washer helps meet industry hygiene standards, reduces contamination risks, and ensures compliance with food safety regulations like HACCP and FDA guidelines.

Result: Using a plastic pallet washer ensures your business complies with strict hygiene and food safety standards.

Enhanced Cleaning Efficiency and Speed

Manual pallet cleaning is a time-consuming process that requires significant labor and attention to detail. Employees must physically scrub, rinse, and dry each pallet by hand, which can be both inefficient and inconsistent. Additionally, this method can lead to worker fatigue and increased labor costs.

Plastic pallet washers, on the other hand, provide an automated solution that cleans multiple pallets simultaneously, significantly speeding up the process. With the use of high-pressure jets and powerful cleaning mechanisms, automated pallet washers can clean pallets much faster than manual labor, enabling your business to handle higher volumes of pallets without compromising on cleanliness.

Result: A plastic pallet washer enhances cleaning speed, reduces manual labor, and boosts productivity.

Cost Savings in the Long Run

At first glance, investing in a plastic pallet washer may seem like a significant upfront cost. However, over time, it can provide substantial savings by reducing labor costs, increasing cleaning efficiency, and prolonging the lifespan of your pallets.

Manual cleaning requires more workers, more time, and more resources like water and cleaning chemicals. An automated plastic pallet washer reduces the need for a large cleaning staff and minimizes waste by using precise amounts of water and chemicals. Furthermore, by regularly cleaning your pallets with a machine designed for the job, you can extend the lifespan of your plastic pallets, reducing the need for costly replacements.

Result: The upfront investment in a plastic pallet washer will pay off through long-term cost savings in labor, water, and pallet replacement costs.

Water and Energy Efficiency

Plastic pallet washing often involves significant water usage, especially when cleaning by hand. Workers may leave water running or use more detergent than necessary, resulting in water waste and higher utility bills. In contrast, plastic pallet washers are engineered to be water-efficient. Many modern models include closed-loop water systems, where water is filtered, purified, and recycled for multiple washes, dramatically reducing water consumption.

Additionally, many automated plastic pallet washers are designed with energy-saving features. For example, they may incorporate energy-efficient motors and low-energy drying systems, reducing the overall energy cost of pallet washing.

Result: A plastic pallet washer reduces water and energy consumption, making the process more environmentally friendly and cost-effective.

Consistent Cleaning Quality

When cleaning pallets manually, it’s easy for inconsistencies to arise—whether due to worker fatigue, different cleaning methods, or time constraints. These inconsistencies can lead to improperly cleaned pallets, which could potentially harbor harmful contaminants.

A plastic pallet washer ensures that each pallet is cleaned to the same high standards every time. Automated systems are designed to deliver consistent results, with features like adjustable pressure settings, uniform water distribution, and timed wash cycles. As a result, you can be confident that every pallet is thoroughly cleaned, reducing the risk of contamination or cross-contamination.

Result: Consistent, high-quality cleaning, providing peace of mind that your pallets are always clean and sanitized.

Easy Maintenance and Longevity

Plastic pallets endure heavy use, and the cleaning equipment they require must also be durable. Traditional cleaning methods—especially those relying on manual labor—can be inconsistent, leading to overuse of cleaning agents, water, and equipment. In contrast, plastic pallet washers are designed to handle the rigors of high-volume use, offering low maintenance and long-term durability.

Modern plastic pallet washers come with features that make them easy to maintain, such as self-cleaning cycles, clear maintenance schedules, and real-time diagnostics that allow businesses to track performance and identify issues before they arise. This proactive maintenance minimizes downtime and ensures that the equipment lasts for years.

Result: A well-maintained plastic pallet washer helps you achieve maximum uptime and long-term operational efficiency.

Versatility for Different Pallet Types

While plastic pallets are the focus of this article, many industries also use other types of pallets, including wooden and metal pallets. Some plastic pallet washers are designed with adjustable settings and interchangeable parts, allowing them to clean various types of pallets with ease. Whether your business uses plastic, wooden, or mixed materials, a versatile pallet washer can handle them all.

This flexibility makes plastic pallet washers suitable for multi-purpose environments, saving your business from having to invest in multiple machines for different types of pallets.

Result: A plastic pallet washer offers flexibility for cleaning different pallet materials, reducing the need for multiple machines.

Conclusion

Investing in a plastic pallet washer brings numerous advantages to businesses, particularly those operating in high-volume environments where hygiene, efficiency, and cost savings are essential. From ensuring consistent hygiene standards to reducing labor costs and increasing cleaning efficiency, a plastic pallet washer can help streamline your pallet cleaning process, improve overall productivity, and contribute to long-term savings.

At LONKIA Machinery, we specialize in providing high-performance, automated plastic pallet washers designed to meet the needs of various industries. Contact us today to learn how we can help improve your pallet washing process and ensure your operations stay clean and efficient.