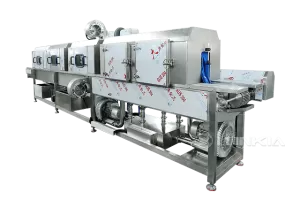

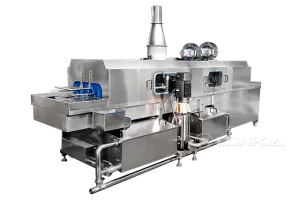

A pallet washing machine is essential for maintaining hygiene and efficiency in industries like food processing, pharmaceuticals, logistics, and manufacturing. These machines help eliminate bacteria, dirt, and contaminants, ensuring pallets meet strict HACCP, FDA, and ISO hygiene standards.

However, to keep your pallet washing equipment running at optimal performance, regular cleaning and maintenance are essential. Poor maintenance can lead to inefficient cleaning, increased downtime, and expensive repairs. In this guide, we’ll explore the best practices for cleaning and maintaining pallet washers to extend their lifespan and improve efficiency.

🔹 Why Proper Cleaning & Maintenance of Pallet Washers Is Essential

✅ Ensures consistent cleaning performance – Prevents residue buildup and contamination.

✅ Reduces equipment downtime – Avoids unexpected malfunctions and costly repairs.

✅ Improves energy and water efficiency – Keeps the system running at peak efficiency.

✅ Extends machine lifespan – Prevents wear and tear on key components.

✅ Ensures regulatory compliance – Meets industry sanitation and hygiene standards.

🔹 Example:

A food processing company that followed a structured maintenance plan for its pallet washers reduced downtime by 40%, improving overall production efficiency.

🔹 Daily Cleaning & Maintenance Checklist

To ensure your pallet washer operates efficiently, follow these daily maintenance steps:

✅ Clean the Spray Nozzles

✔ Check for clogs, residue, and mineral buildup.

✔ Use a soft brush or compressed air to remove debris.

✔ Replace damaged nozzles to maintain even water pressure.

🔹 Why?

Blocked nozzles reduce cleaning effectiveness, leaving contaminants on pallets.

✅ Inspect the Conveyor System

✔ Ensure chains, rollers, and belts are aligned properly.

✔ Check for wear, misalignment, or loose components.

✔ Lubricate moving parts as per manufacturer guidelines.

🔹 Why?

A faulty conveyor can cause pallet misalignment, incomplete washing, and breakdowns.

✅ Monitor Water Pressure & Temperature

✔ Verify that the machine maintains the correct water pressure.

✔ Ensure the heating system reaches the recommended temperature for sanitation.

🔹 Why?

Improper water pressure or temperature can lead to poor cleaning results and hygiene risks.

✅ Check Detergent & Chemical Levels

✔ Ensure the correct detergent concentration is being used.

✔ Refill chemical dispensers as needed.

🔹 Why?

Too little detergent leads to ineffective cleaning, while too much can cause residue buildup.

✅ Run a Short Test Cycle

✔ Observe water flow, spray power, and conveyor movement.

✔ Listen for unusual noises, which could indicate a mechanical issue.

🔹 Why?

A test cycle helps detect minor issues before they escalate into major failures.

🔹 Weekly Deep Cleaning & System Checks

✅ Clean the Interior & Exterior

✔ Remove scale, grease, and dirt buildup inside the washing chamber.

✔ Wipe down exterior panels to prevent dust and contamination.

🔹 Why?

Grease and residue can affect cleaning efficiency and increase energy consumption.

✅ Inspect & Clean the Water Filtration System

✔ Check filters for clogs or buildup.

✔ Replace or clean filters to maintain water quality.

🔹 Why?

A dirty filtration system reduces water efficiency, leading to higher detergent use and weaker cleaning performance.

✅ Test the Drying System

✔ Ensure hot air or drying mechanisms function properly.

✔ Remove any blockages in air vents or drying fans.

🔹 Why?

Proper drying prevents moisture buildup, which can lead to mold and bacteria growth.

🔹 Monthly Preventive Maintenance Tasks

✅ Inspect the Heating Elements

✔ Look for signs of wear, scaling, or malfunction.

✔ Ensure consistent temperature regulation.

🔹 Why?

Heating issues can cause incomplete sanitization, leading to contamination risks.

✅ Check Pumps & Valves

✔ Inspect for leaks, corrosion, or low water pressure.

✔ Tighten loose fittings and replace worn-out pump seals.

🔹 Why?

Faulty pumps reduce cleaning power and increase water waste.

✅ Lubricate Bearings & Moving Parts

✔ Apply manufacturer-approved lubricants to prevent wear.

✔ Avoid over-lubrication, which can attract dust and debris.

🔹 Why?

Proper lubrication extends machine lifespan and efficiency.

🔹 Annual Maintenance & Professional Servicing

✅ Schedule a Full System Inspection

✔ Have a certified technician check electrical and mechanical components.

✔ Perform a deep clean of internal pipes and spray systems.

🔹 Why?

Professional servicing helps prevent unexpected breakdowns and ensures regulatory compliance.

✅ Replace Worn-Out Components

✔ Identify and replace aging parts like belts, hoses, and seals.

✔ Upgrade outdated components for improved efficiency.

🔹 Why?

Replacing parts before failure minimizes downtime and costly repairs.

🔹 Common Signs Your Pallet Washer Needs Immediate Maintenance

If you notice any of these issues, schedule maintenance immediately:

❌ Uneven water pressure → Clogged nozzles or failing pumps.

❌ Inconsistent water temperature → Heating element malfunction.

❌ Frequent breakdowns → Poor lubrication or worn-out components.

❌ Increased detergent or water consumption → Inefficient cleaning system.

❌ Unusual noises → Misaligned conveyor belts or loose mechanical parts.

🔹 Best Practices for Maximizing Pallet Washer Lifespan

🔸 Follow Manufacturer Guidelines – Use recommended detergents, lubricants, and settings.

🔸 Train Staff on Proper Use – Ensure operators follow standard operating procedures.

🔸 Implement a Preventive Maintenance Schedule – Routine checks prevent major failures.

🔸 Monitor Performance Metrics – Track water, energy, and detergent usage to detect inefficiencies.

🚀 Example: A logistics company that implemented a strict maintenance schedule increased the lifespan of its pallet washers by 30%, reducing replacement costs and downtime.

🔹 Conclusion: Keep Your Pallet Washer in Peak Condition

By implementing daily, weekly, monthly, and annual maintenance routines, businesses can:

✅ Reduce downtime and maximize efficiency.

✅ Ensure compliance with industry hygiene standards.

✅ Lower repair and replacement costs.

✅ Improve cleaning performance and water efficiency.

At LONKIA Machinery, we provide high-quality pallet washing machines along with expert maintenance support. Contact us today for customized maintenance plans and spare parts solutions! 🚀