In the food processing industry, continuous fryer for sale is an important equipment to improve production efficiency and food quality. As market demand increases, choosing the right continuous deep fryer becomes especially critical. This article will help you understand how to select the right model of continuous fryer for your plant and ensure that the equipment will meet your production needs.

Determining production needs and capacity

When choosing the continuous fryer for sale, you first need to identify your production needs and capacity requirements. Different models of fryers have different capacities, with solutions for small to large-scale production. Choose your equipment based on factors such as your line speed, food type and hourly output to ensure it can handle your production scale.

Choosing the right type of heating

Heating methods for continuous food fryers are usually categorized into two types: electric heating and gas heating. Electrically heated fryers are suitable for food products that require precise heating temperatures, while gas-heated models offer better heating results in high-temperature environments and are suitable for some high-efficiency production needs. Choose the right heating method according to your production environment and energy budget, so as to improve energy efficiency and equipment performance.

Consider the degree of automation

Modern continuous fryer for sale have highly automated features, such as automatic temperature control, automatic slag draining, and oil filtration systems. These features not only improve production efficiency, but also ensure that the quality of the food remains consistent from batch to batch. If your production needs are large, it is recommended to choose equipment with these automated features to reduce manual intervention and improve the stability and safety of your production line.

Material and durability

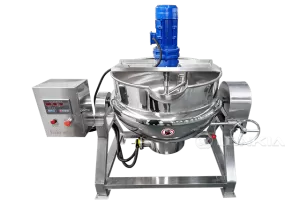

The material of your continuous fryer has a direct impact on how long it lasts and how easy it is to clean and maintain. Most high-quality fryers are made of stainless steel, which has good corrosion resistance and high temperature resistance. Choosing the stainless steel material not only ensures the long-term use of the equipment, but also facilitates daily cleaning and maintenance.

After-sales service and guarantee

When buying a continuous fryer, in addition to focusing on the performance of the equipment itself, you also need to consider the after-sales service. A reliable supplier should provide perfect after-sales service, including equipment installation, commissioning and regular maintenance. In addition, the warranty period of the equipment is also an important criterion to measure its reliability. As a professional food manufacturer, you can rest assured that you will get patient service and high quality machines when you choose Lonkia.

In conclusion, choosing the right continuous fryer for sale is key to ensuring productivity and product quality. During the selection process, you need to consider factors such as capacity requirements, heating methods, automation features, materials and after-sales service. Only by taking these factors into consideration can you choose the best continuous food fryer to improve productivity and ensure consistent food quality.