As industries move towards sustainable operations, businesses are seeking ways to reduce water and energy consumption without compromising hygiene and efficiency. Pallet washing, essential for industries like food processing, pharmaceuticals, logistics, and manufacturing, can be highly resource-intensive if not optimized.

By implementing eco-friendly washing strategies, companies can lower utility costs, meet environmental regulations, and enhance operational efficiency. This blog explores the best practices for reducing water and energy usage in pallet washing while maintaining hygiene standards.

🔹 Implement a Water Recycling System

✅ Why It Matters:

Traditional pallet washers consume large amounts of water, leading to high operating costs and environmental waste. Recycling water reduces both.

🔧 Optimization Strategies:

✔ Install filtration systems to remove debris and contaminants, making water reusable.

✔ Use multi-stage washing – Separate pre-wash, main wash, and rinse cycles to optimize water use.

✔ Employ sedimentation tanks to settle out solids before reusing water.

🔹 Example:

A closed-loop water recycling system can reduce water consumption by 50-80%, cutting costs while maintaining cleanliness.

🔹 Optimize Water Pressure and Flow

✅ Why It Matters:

Excessive water pressure wastes water and energy, while insufficient pressure reduces cleaning effectiveness.

🔧 Optimization Strategies:

✔ Use high-efficiency spray nozzles that reduce flow but maintain cleaning power.

✔ Adjust pressure settings – Moderate pressure cleans effectively while reducing waste.

✔ Optimize nozzle placement for better coverage and reduced water use.

🔹 Example:

Switching to low-flow, high-impact nozzles can cut water usage by up to 30% without reducing washing quality.

🔹 Reduce Energy Use with Smart Heating Systems

✅ Why It Matters:

Heating water for washing is one of the most energy-intensive processes. Optimizing heat use can lower costs and carbon footprint.

🔧 Optimization Strategies:

✔ Use energy-efficient heating elements that consume less power.

✔ Install heat exchangers to recover and reuse heat from wastewater.

✔ Lower temperature settings when possible – Some cleaning agents work effectively at lower temperatures.

🔹 Example:

A heat recovery system can reduce energy consumption by up to 40%, significantly lowering utility bills.

🔹 Automate the Washing Process

✅ Why It Matters:

Manual washing wastes water and energy due to inconsistent cleaning times and excessive use of resources.

🔧 Optimization Strategies:

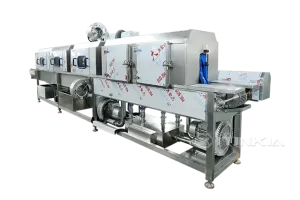

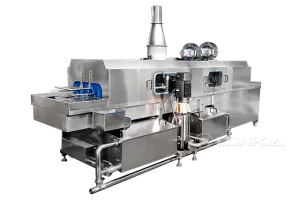

✔ Upgrade to an automated pallet washer for precise control over water and energy use.

✔ Use smart sensors to detect dirt levels and adjust washing cycles accordingly.

✔ Program variable wash cycles to use only the necessary amount of water and energy.

🔹 Example:

Automated washers with sensor-based controls can reduce water and energy consumption by up to 50% compared to manual washing.

🔹 Choose Eco-Friendly Detergents and Cleaning Agents

✅ Why It Matters:

Harsh chemicals increase environmental pollution and require excessive water for rinsing.

🔧 Optimization Strategies:

✔ Use biodegradable, low-foam detergents to reduce chemical waste.

✔ Optimize detergent dosing with automated systems to prevent overuse.

✔ Switch to enzyme-based cleaners, which work effectively at lower temperatures, reducing energy demand.

🔹 Example:

Switching to low-foam, biodegradable detergents can cut rinsing water consumption by 20-30%.

🔹 Optimize Drying Efficiency

✅ Why It Matters:

Traditional heat-based drying systems consume large amounts of energy. Optimizing drying can reduce energy waste.

🔧 Optimization Strategies:

✔ Use high-speed air blowers instead of heat drying to reduce power consumption.

✔ Optimize airflow direction to improve drying speed and efficiency.

✔ Utilize residual heat from washing cycles to pre-dry pallets before air drying.

🔹 Example:

Switching to air-blower drying systems instead of heat-based dryers can cut energy costs by 30-50%.

🔹 Perform Regular Maintenance to Maximize Efficiency

✅ Why It Matters:

Poorly maintained pallet washers consume more water and energy due to inefficiencies.

🔧 Optimization Strategies:

✔ Clean spray nozzles and filters regularly to prevent clogs.

✔ Inspect heating elements and pumps to ensure efficient performance.

✔ Monitor and recalibrate sensors for accurate resource usage.

🔹 Example:

A monthly maintenance schedule helps prevent water and energy waste, ensuring the system runs efficiently.

🔹 Conclusion: A Sustainable Approach to Pallet Washing

By implementing eco-friendly pallet washing strategies, businesses can:

✅ Reduce water and energy consumption while maintaining cleaning effectiveness.

✅ Lower operational costs through smart heating and water recycling.

✅ Improve sustainability efforts to meet environmental regulations.

✅ Enhance equipment lifespan with optimized cleaning processes.

At LONKIA Machinery, we offer energy-efficient pallet washing solutions with customizable eco-friendly features. Contact us today to explore sustainable pallet washing systems tailored to your industry needs! 🚀