Recently, an Egyptian food processing enterprise customer successfully purchased a complete set of french fries processing machines from Lonkia, which is attracted by Lonkia's mature technical solutions, equipment performance and perfect service after in-depth investigation of several suppliers. After a thorough investigation of several suppliers, the customer was attracted by lonkia's mature technical solutions, equipment performance and perfect service and finally decided to cooperate with lonkia. Currently, the production line has been successfully put into operation in the customer's factory and has been highly recognized.

Advantages of Lonkia French fries production line

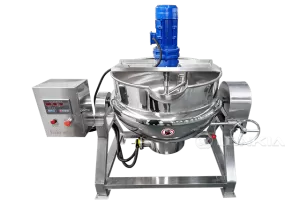

- Food-grade materials, easy to clean and maintain: Lonkia French fries processing machines are made of 304 stainless steel, which meets the international food safety standards, and the key components can be disassembled and cleaned to ensure hygiene and prolong service life.

- Compact structure and reasonable layout: the whole line consists of cleaning and peeling, cutting, blanching, deep-frying, cooling, freezing, etc. The process is scientific and easy to operate, which makes it easy for customers to get started quickly and manage efficiently.

- Automation control improves efficiency: key processes are equipped with intelligent control system, realizing precise temperature control and automatic operation, significantly reducing manual intervention and energy consumption.

Support from lonkia's professional technical team

During the project implementation, lonkia provided Egyptian customers with integrated technical services from equipment selection, French fires production line layout to operation training. After the installation is completed, technical engineers provide remote guidance and video teaching to help customers quickly master the use of each piece of equipment and maintenance points. For the local raw material, lonkia also assisted in optimizing the cutting size and frying time to ensure that the final product is golden in color and crispy in texture.

The project was successfully delivered and put into production

The whole production line was delivered in less than two months, and lonkia strictly followed the project schedule to fulfill all the milestones. During the installation and commissioning period, the equipment operated stably and met all the targets. The customer is satisfied with the performance of automatic french fry maker, and has formally put it into mass production, and plans to continue to purchase lonkia related equipment in the subsequent expansion.

At present, the french fries processing machine has been successfully delivered to the customer's factory and installed with the assistance of Lonkia engineers. After the machine was put into production, it has been running stably and the quality of french fries has met the customer's expectation, and the daily production capacity has been significantly increased. The customer expressed that they are very satisfied with Lonkia's equipment and service, and plan to continue to purchase related equipment in the future expansion, and develop long-term cooperation with Lonkia.