A well-maintained potato chips processing line is key to ensuring high efficiency, product quality, and long-term operational success. Regular maintenance helps prevent breakdowns, reduces downtime, and extends the lifespan of your equipment. Below are essential maintenance tips to keep your potato chips production line running smoothly.

Regular Cleaning and Sanitation

Residue buildup from potatoes, oil, and starch can lead to contamination and decreased efficiency. Keeping all equipment clean is crucial for maintaining hygiene and preventing operational issues.

✅ Best Practices:

Clean slicing machines, conveyors, and frying systems after each production cycle.

Use food-grade cleaning agents to remove oil and starch buildup.

Ensure drains and waste disposal systems are cleared regularly to prevent clogging.

Inspect and Maintain Slicing Machines

Slicing is one of the most critical steps in potato chips production. Dull blades or improper calibration can result in uneven chips, leading to product inconsistencies and waste.

✅ Best Practices:

Regularly sharpen or replace slicing blades to maintain precision.

Check the alignment and speed settings to ensure uniform slicing.

Inspect moving parts for wear and lubricate as needed.

Ensure Proper Functioning of Blanching and Drying Systems

Blanching helps remove excess starch, while drying ensures that chips fry evenly without absorbing too much oil. Malfunctioning in these systems can lead to poor texture and quality issues.

✅ Best Practices:

Monitor water temperature and flow rate in blanching machines.

Check drying fans and heating elements to ensure proper moisture removal.

Regularly clean filters and drainage systems to prevent blockages.

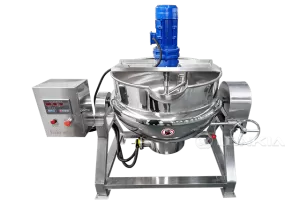

Maintain Frying Equipment for Optimal Performance

The frying process is critical for achieving the perfect crispy texture. Poor maintenance can lead to uneven frying, excess oil usage, and quality defects.

✅ Best Practices:

Monitor oil temperature to ensure consistency and prevent overcooking.

Regularly filter and replace frying oil to maintain product quality.

Clean heat exchangers and burners to optimize fuel efficiency.

Keep De-Oiling and Cooling Systems in Check

Excess oil retention can affect both chip texture and shelf life. Proper de-oiling and cooling are essential for a high-quality end product.

✅ Best Practices:

Inspect centrifugal de-oiling machines for wear and replace worn-out components.

Ensure cooling conveyors are free from oil buildup and properly ventilated.

Check the speed and alignment of the cooling belt to maintain consistent chip texture.

Preventive Maintenance for Packaging Machines

The final step in the potato chips processing line is packaging, where malfunctions can lead to delays, product waste, and contamination risks.

✅ Best Practices:

Inspect weighing and filling systems to prevent portioning errors.

Regularly calibrate sealing and nitrogen flushing machines for freshness preservation.

Keep sensors and conveyors clean to avoid product jams.

Implement a Predictive Maintenance Schedule

A proactive maintenance approach helps detect potential failures before they cause serious downtime.

✅ Best Practices:

Use IoT-enabled sensors to monitor machine performance in real time.

Maintain a log of all inspections and repairs to track equipment conditions.

Train operators on basic troubleshooting to handle minor issues efficiently.

Conclusion

Routine maintenance of your potato chips processing line not only extends equipment lifespan but also ensures high efficiency and consistent product quality. By cleaning regularly, inspecting key components, and adopting predictive maintenance, manufacturers can minimize downtime, reduce costs, and maximize productivity.

At LONKIA Machinery, we offer advanced potato chips processing equipment and expert support to keep your production line running at peak performance. Contact us today for tailored solutions!