In the modern food processing industry, the frozen potato production line has become one of the core equipment in the manufacturing of frozen foods such as French fries and potato cubes. For many processors, understanding the capacity of a frozen potato production line is a key factor in making investment decisions. So, how many finished products can a French fries making machine factory produce per hour?

What factors affect capacity?

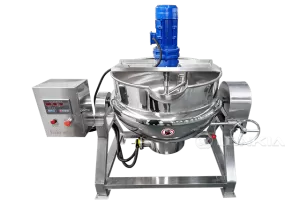

The capacity of fries maker machine is affected by a number of factors. First of all, the configuration of the equipment and the degree of automation directly determines the productivity. Lonkia's frozen potato production line, for example, is equipped with state-of-the-art automatic vegetable washers, precision potato cutters, vegetable blanchers, continuous fryers and freezers, making the entire production process efficient and intelligently managed. These equipments not only ensure the smooth operation of the production line, but also greatly improve the production efficiency.

Specifically, the variety of potatoes, the way they are handled, as well as the production process (e.g., the time and temperature of the blanching, frying and freezing processes) also affect the final yield. For example, the selection of high-quality potatoes, precise cutting techniques and scientific frying times can effectively reduce raw material waste and further increase production capacity.

How can capacity be increased?

In order to increase the capacity of French fries making machine factory, the production process must be optimized in several ways. First of all, choosing the right cutter and fryer is crucial. For example, precise cutting technology ensures that potatoes are sliced evenly, reducing waste and increasing productivity. Secondly, time and temperature control for frying and cooling should be precise to avoid overcooking or underfrying of the product, which can affect yield and quality.

In addition, the modernized production line adopts PLC automatic control system, which is able to intelligently regulate the operation speed of each link so as to increase the overall output. By optimizing each link, the overall efficiency of the production line is significantly improved and the output can be effectively increased.

Comparison of production capacities of different line sizes

The production capacity of a frozen potato line is not only determined by the size of the equipment, but also by the configuration of the line. For example, Lonkia frozen French fries processing line with different equipment configurations will typically produce 500 kg/hour on a small line, suitable for small factories or regional processing needs. Medium-sized lines, on the other hand, typically produce between 1,000 and 1,500 kilograms per hour, which is ideal for most medium-sized processors. For large plants and companies with huge demand, choosing a line with a capacity of up to 2,000 kilograms to 3,000 kilograms per hour will ensure that the market demand is met.

To sum up, the production capacity of French fries making machine factory is affected by several factors, but through reasonable equipment selection and optimization of the production process, the output can be effectively increased. Knowing the hourly production capacity can help enterprises better plan the production scale and improve production efficiency and market competitiveness. By investing in efficient and intelligent equipment, you can maximize your production line capacity while ensuring product quality.