In industries like food processing, pharmaceuticals, logistics, and manufacturing, plastic pallets play a crucial role in transporting goods efficiently. However, keeping these pallets clean is just as important as using them. Manually washing plastic pallets can be time-consuming, labor-intensive, and inconsistent, leading to increased operational costs.

A plastic pallet washer provides an automated and efficient cleaning solution that not only saves time but also significantly reduces labor costs. In this blog, we’ll explore how investing in a plastic pallet washer can improve productivity, hygiene, and cost-effectiveness for your business.

Automating the Cleaning Process to Save Time

The Challenge:

Manual washing of plastic pallets requires workers to spend hours scrubbing, rinsing, and sanitizing each pallet individually. This process slows down operations and creates inconsistencies in cleanliness.

✅ The Solution: Automated Washing

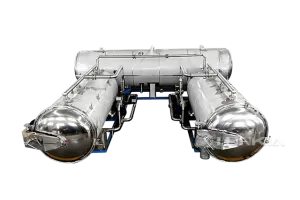

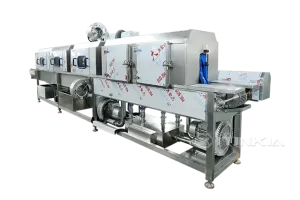

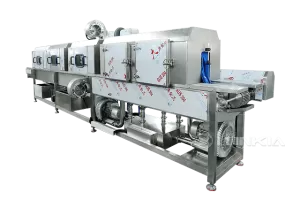

A plastic pallet washer streamlines the cleaning process by using high-pressure water jets, detergent cycles, and automated scrubbing to clean multiple pallets simultaneously.

Key Time-Saving Benefits:

- Fast Cleaning Cycles – Cleans pallets in a fraction of the time compared to manual washing.

- Continuous Operation – Some models allow conveyorized cleaning, meaning pallets are cleaned without stopping workflow.

- Consistent Results – Eliminates time wasted on re-washing improperly cleaned pallets.

Result: Businesses experience faster turnaround times, ensuring pallets are quickly cleaned and ready for reuse.

Reducing Labor Costs by Minimizing Manual Work

The Challenge:

Handwashing plastic pallets requires a dedicated workforce, increasing labor expenses while adding risks of fatigue and human error. Workers spend valuable time on cleaning tasks instead of focusing on other critical production activities.

✅ The Solution: Labor Reduction Through Automation

A plastic pallet washer eliminates the need for manual scrubbing and rinsing, reducing the number of workers required for cleaning operations.

Labor-Cost Saving Benefits:

- Reduces workforce needs – Fewer employees are needed for pallet washing, allowing them to be reassigned to more value-adding tasks.

- Minimizes repetitive labor injuries – Reducing manual washing lowers the risk of worker fatigue, strain, and workplace injuries.

- Increases efficiency per worker – One employee can operate the washer, handling large pallet volumes in the time it would take multiple workers to clean manually.

Result: Significant reductions in labor costs, while increasing overall operational efficiency.

Ensuring Consistent and Hygienic Cleaning

The Challenge:

Manual washing often leads to inconsistent cleaning, leaving behind dirt, bacteria, or contaminants. This can result in hygiene risks, particularly in food processing and pharmaceutical industries where strict sanitation standards must be met.

✅ The Solution: High-Pressure and Sanitizing Cycles

A plastic pallet washer ensures every pallet is cleaned to the same high standard, using:

- High-pressure water jets to remove debris and contaminants.

- Detergent application for effective sanitation.

- Hot water or steam cycles for bacteria and germ elimination.

Hygiene and Compliance Benefits:

- Meets strict food safety and hygiene standards (HACCP, FDA, and GMP compliant).

- Prevents cross-contamination, ensuring pallets don’t spread bacteria between shipments.

- Automated disinfection removes the risk of human error in cleaning.

Result: A cleaner, safer working environment that reduces health risks and product contamination concerns.

Lowering Water and Detergent Costs

The Challenge:

Manual pallet washing wastes large amounts of water and cleaning detergents, leading to higher utility bills and environmental impact. Workers often overuse water and chemicals, which increases operational expenses.

✅ The Solution: Water Recycling and Efficient Chemical Usage

A plastic pallet washer is designed to optimize water and detergent consumption through:

- Water recycling systems that filter and reuse water, cutting down on waste.

- Automated detergent dispensers that release precise amounts, preventing excess use.

- Energy-efficient heating systems that lower electricity consumption.

Cost-Saving Benefits:

- Reduces water consumption by up to 50-70%.

- Lowers chemical costs by using only the required amount of detergent.

- Eco-friendly operation, helping businesses meet sustainability goals.

Result: Lower utility costs and a reduced environmental footprint.

Maximizing Productivity with Continuous Workflow

The Challenge:

Manually cleaning pallets disrupts workflow, leading to delays in production and logistics. Slow pallet turnaround can cause bottlenecks, especially in high-volume operations.

✅ The Solution: Integrated and Automated Washing Systems

A plastic pallet washer integrates smoothly into your workflow, allowing for continuous operation without slowing down production.

Productivity-Boosting Benefits:

- Conveyorized washing systems keep pallets moving without interruptions.

- Quick drying options (hot air blowers or drip-drying) ensure pallets are ready for immediate reuse.

- Minimal downtime, as the system operates automatically while staff focus on other tasks.

Result: Increased throughput and efficiency, ensuring smooth operations across all departments.

Conclusion: A Smart Investment for Time and Cost Savings

A plastic pallet washer is a game-changer for businesses that require frequent and thorough cleaning of pallets. By automating the cleaning process, companies can:

✅ Reduce labor costs by minimizing manual work.

✅ Save time with faster, more efficient pallet cleaning.

✅ Improve hygiene and consistency, ensuring compliance with safety standards.

✅ Lower water and detergent usage, reducing operating expenses.

✅ Enhance overall productivity, eliminating workflow disruptions.

At LONKIA Machinery, we offer high-performance plastic pallet washing systems designed to boost efficiency, reduce costs, and improve hygiene standards. Contact us today to learn how our automated pallet washing solutions can benefit your business!