In the logistics and warehousing industry, maintaining clean and contamination-free pallets is essential for ensuring product safety, regulatory compliance, and operational efficiency. Plastic pallets are widely used for transporting goods, but without proper cleaning, they can harbor bacteria, mold, dust, and chemical residues, posing risks to both food and non-food supply chains.

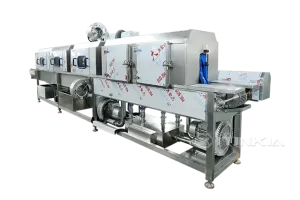

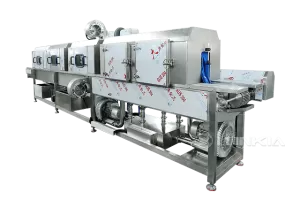

A plastic pallet washer is a crucial solution for maintaining hygiene in distribution centers, warehouses, and logistics hubs. By automating the cleaning process, these machines ensure that pallets remain free from contaminants, reducing the risk of cross-contamination, product damage, and safety hazards.

In this article, we’ll explore how plastic pallet washers improve hygiene, their key benefits, and why they are essential for businesses focused on clean and efficient logistics operations.

🔹 The Importance of Pallet Hygiene in Logistics and Warehousing

Plastic pallets are reused across multiple locations, warehouses, and transportation networks. Without proper washing, they can become carriers of:

❌ Dirt, dust, and debris – Accumulates from frequent handling and storage.

❌ Bacterial growth – Pathogens like E. coli, Salmonella, and Listeria can spread through contaminated pallets.

❌ Chemical residues – Leftover substances from previous shipments.

❌ Pest contamination – Rodents and insects can leave traces on unclean pallets.

❌ Cross-contamination – Spreads contaminants between different goods (e.g., food and non-food products).

🔹 Example:

A warehouse handling both food and industrial chemicals found that cross-contaminated pallets led to damaged goods and regulatory compliance issues. Installing a plastic pallet washer eliminated contamination risks.

🔹 How a Plastic Pallet Washer Enhances Hygiene

A plastic pallet washer is an automated cleaning system that effectively removes dirt, bacteria, and chemical residues using high-pressure water jets, detergents, and heat disinfection. Here’s how it helps maintain hygiene standards:

✅ Thorough Cleaning with High-Pressure Water Jets

✔ Removes stubborn dirt, dust, and grease.

✔ Ensures even coverage across the entire pallet surface.

✔ Prevents buildup of organic matter that can lead to bacterial growth.

🔹 Example:

A logistics center distributing fresh produce uses high-pressure pallet washing to prevent contaminants from transferring to food shipments.

✅ Eliminates Bacteria & Pathogens with Hot Water & Chemical Disinfection

✔ Hot water (up to 85°C) kills bacteria, viruses, and mold spores.

✔ Some models offer steam disinfection for additional sanitation.

✔ Food-safe detergents break down organic contaminants.

🔹 Example:

A warehouse storing dairy products reduced Listeria contamination risks by switching to a pallet washer with hot water sanitation.

✅ Prevents Cross-Contamination Between Goods

✔ Ensures that pallets used for food, pharmaceuticals, and industrial materials are properly cleaned.

✔ Removes previous residues, preventing mixing of different product categories.

🔹 Example:

A warehouse handling pharmaceutical supplies and cleaning chemicals installed a dedicated pallet washing system to ensure separate cleaning cycles.

✅ Faster, More Efficient Cleaning Process

✔ Processes hundreds of pallets per hour, reducing manual labor.

✔ Ensures consistent cleaning quality without human error.

✔ Eliminates the need for manual scrubbing and drying.

🔹 Example:

A distribution hub reduced pallet turnaround time by 60% after installing an automated pallet washer, improving warehouse efficiency.

✅ Reduces Mold Growth & Odor with High-Speed Drying

✔ Removes moisture, preventing bacteria and mold growth.

✔ Ensures pallets are dry before reuse, maintaining hygiene.

🔹 Example:

A beverage distributor reduced mold-related product spoilage by 80% after switching to a pallet washer with a drying function.

🔹 Benefits of Using a Plastic Pallet Washer in Logistics & Warehousing

✔ Ensures Compliance with Hygiene Regulations

✅ Meets HACCP, FDA, and ISO 22000 hygiene standards.

✅ Essential for warehouses dealing with food, pharmaceuticals, and sensitive products.

✔ Improves Supply Chain Efficiency

✅ Reduces contamination risks and product recalls.

✅ Helps maintain cleaner storage areas and transport vehicles.

✔ Lowers Operational Costs

✅ Automated cleaning reduces the need for manual labor.

✅ Water recycling systems cut down on water consumption.

✔ Enhances Brand Reputation & Customer Trust

✅ Clean pallets help ensure safer, higher-quality deliveries.

✅ Companies with high hygiene standards attract more business partnerships.

🔹 How to Choose the Right Plastic Pallet Washer for Your Business

✅ Capacity & Throughput Speed

✔ Small-scale warehouses → Compact models (50-100 pallets/hour).

✔ Large logistics hubs → High-capacity industrial washers (500+ pallets/hour).

✅ Washing & Sanitization Features

✔ High-pressure cleaning for tough residues.

✔ Hot water and steam disinfection for food-related pallets.

✔ Chemical sanitization options for pharmaceutical warehouses.

✅ Energy & Water Efficiency

✔ Water filtration and recycling reduce consumption.

✔ Low-energy motors help save on electricity.

✅ Robust Stainless Steel Construction

✔ 304/316 stainless steel ensures durability and hygiene.

✔ Corrosion-resistant surfaces for long-term performance.

🔹 Example:

A logistics provider handling food and retail goods chose a pallet washer with multiple washing cycles, ensuring hygiene standards for different industries.

🔹 Best Practices for Maintaining a Plastic Pallet Washer

To ensure long-lasting performance, follow these maintenance tips:

🛠️ Daily:

✔ Inspect spray nozzles for blockages.

✔ Check water pressure and temperature settings.

🛠️ Weekly:

✔ Clean the filtration system to prevent residue buildup.

✔ Lubricate moving conveyor parts for smooth operation.

🛠️ Monthly:

✔ Deep clean the interior washing chamber.

✔ Inspect pumps, heating elements, and drying fans.

🛠️ Annually:

✔ Schedule professional servicing to ensure compliance and efficiency.

🔹 Conclusion: Why Every Warehouse Needs a Plastic Pallet Washer

For logistics and warehousing operations, a plastic pallet washer is an essential investment for maintaining hygiene, efficiency, and product safety. By automating the cleaning process, businesses can eliminate bacteria, prevent cross-contamination, and comply with strict industry regulations.

🔑 Key Takeaways:

✅ Removes dirt, bacteria, and chemical residues for cleaner logistics operations.

✅ Prevents cross-contamination in warehouses handling food, pharmaceuticals, and industrial goods.

✅ Speeds up cleaning cycles, reducing manual labor and improving efficiency.

✅ Saves water and energy with recycling systems.

✅ Ensures regulatory compliance, enhancing brand trust and reputation.

At LONKIA Machinery, we provide high-efficiency plastic pallet washers for warehouses, distribution centers, and logistics hubs. Contact us today for custom solutions to meet your hygiene needs! 🚀