In industries like food processing, pharmaceuticals, and logistics, pallet washing is an essential task to maintain hygiene and meet strict safety regulations. Traditional methods of cleaning pallets—whether plastic or wooden—can be time-consuming, labor-intensive, and prone to inconsistencies. However, with the advent of automated pallet washers, businesses can streamline this process, improve cleaning efficiency, and enhance overall operational performance.

In this blog, we’ll explore how an automated pallet washer can significantly improve your cleaning efficiency and why investing in one can be a game-changer for your business.

Increased Speed and Throughput

Faster, More Efficient Cleaning

Traditional pallet cleaning methods typically require manual labor, which can be slow and prone to errors. Workers must physically scrub and rinse pallets, a task that takes time, especially when dealing with large quantities. This can cause delays in the workflow and ultimately slow down overall production.

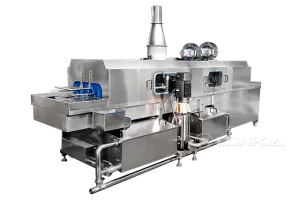

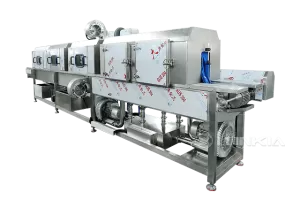

An automated pallet washer, on the other hand, is designed to clean pallets much more quickly and efficiently. These machines can handle high volumes of pallets in a short amount of time, significantly increasing throughput. Automated systems can wash multiple pallets simultaneously, cutting down the time spent on cleaning and allowing employees to focus on other essential tasks.

Result: With an automated system, you’ll see a noticeable increase in the speed of your cleaning process, which translates into improved productivity and efficiency.

Consistent and Reliable Cleaning Quality

Uniform Cleaning Every Time

One of the biggest challenges with manual pallet washing is the inconsistency in cleaning. Human error can lead to missed spots or uneven cleaning, especially when cleaning a large number of pallets. Additionally, manual washing may not always remove stubborn dirt, grease, or contaminants effectively, which can compromise hygiene standards and potentially lead to cross-contamination in sensitive industries like food processing.

Automated pallet washers, however, provide a uniform cleaning process that ensures each pallet is washed thoroughly. These machines use high-pressure water jets, rotating brushes, and sanitizing chemicals to achieve a consistently high-quality clean. The precision of automated cleaning ensures that even hard-to-reach areas are thoroughly sanitized, meeting the highest hygiene standards.

Result: Automated pallet washers provide consistent, high-quality cleaning, helping to maintain strict sanitation standards and food safety regulations.

Reduced Labor Costs

Less Need for Manual Labor

One of the most significant benefits of investing in an automated pallet washer is the reduction in labor costs. With manual pallet washing, you need multiple workers to handle the cleaning process, which can be expensive, especially for large businesses with high-volume needs. Additionally, manual labor increases the likelihood of worker fatigue, which can result in reduced cleaning quality over time.

Automated pallet washers reduce the need for human intervention, allowing businesses to save on labor costs. With fewer workers required for pallet washing, your team can be allocated to more value-added tasks, improving efficiency across other areas of the business.

Result: An automated system cuts labor costs while reducing the risk of human error.

Water and Energy Efficiency

Eco-Friendly and Cost-Effective Solutions

Traditional pallet washing often uses large quantities of water and cleaning chemicals. With manual cleaning, the water may run continuously or be wasted during the washing process, increasing operational costs and impacting the environment.

Automated pallet washers are designed with water-saving technologies such as closed-loop water systems, where water is recycled and reused for subsequent washes. These systems are also designed to optimize water usage, reducing waste and lowering water bills. Moreover, many automated systems incorporate energy-efficient motors and drying technologies to minimize energy consumption.

Result: Automated pallet washers help reduce water and energy usage, making them more eco-friendly and cost-effective over time.

Enhanced Hygiene and Food Safety

Meeting Strict Sanitation Standards

In industries like food processing, pharmaceuticals, and healthcare, pallet washing isn’t just about cleanliness—it’s about meeting strict hygiene and food safety standards. Manual cleaning, due to its inconsistent nature, can lead to inadequate sanitization, which is a serious concern in environments where contamination can have dire consequences.

Automated pallet washers are designed to meet high hygiene standards, with advanced sanitization features such as high-pressure washing, chemical sanitizing, and thermal drying. These features ensure that pallets are not only clean but also free from bacteria, molds, and other harmful contaminants. Many automated systems are also customizable to suit the specific cleaning and sanitizing needs of various industries.

Result: Automated pallet washers provide higher levels of cleanliness and reliability, helping businesses meet strict industry regulations.

Reduced Downtime and Increased Reliability

Continuous Operation with Minimal Maintenance

Manual cleaning processes often require downtime for breaks, shifts, and sometimes for maintenance of cleaning tools. Additionally, workers may not always perform their best under time pressure, leading to delays and reduced productivity.

Automated pallet washers, however, are designed for continuous operation with minimal interruptions. With predictive maintenance features, you can monitor the health of the machine and perform routine maintenance to prevent breakdowns before they occur. Automated systems can work around the clock, ensuring consistent performance and reliable operation.

Result: Automated pallet washers ensure reliable operation and reduce downtime, keeping your operations running smoothly.

Conclusion

Investing in an automated pallet washer offers numerous advantages, from improving cleaning speed and quality to reducing labor costs and enhancing food safety. Whether you are in the food industry, pharmaceuticals, or logistics, automated pallet washers can help you maintain higher standards of hygiene, reduce operational costs, and increase overall efficiency.

At LONKIA Machinery, we offer a range of automated pallet washing solutions that can be tailored to meet the specific needs of your business. Contact us today to learn how we can help you streamline your pallet cleaning process and improve operational performance.