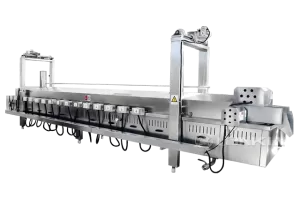

In the modern food processing industry, the continuous potato chips fryer has become a key piece of equipment for improving the efficiency and quality of potato chip production. Its appearance not only effectively simplifies the production process, but also greatly improves the consistency and productivity of the product. This article will specifically discuss the advantages of continuous fryers in potato chip production.

Improved production efficiency

One of the biggest advantages of a continuous fryer is its efficiency. Thanks to its automated operation, it can continuously process large quantities of potato chips without the need for frequent downtime to switch batches. This design allows for much less downtime in the production line, which increases production and boosts the plant's capacity. This feature is especially important for large-scale producers, which can effectively shorten the production cycle and meet the market demand for potato chips.

Ensure uniform frying of potato chips

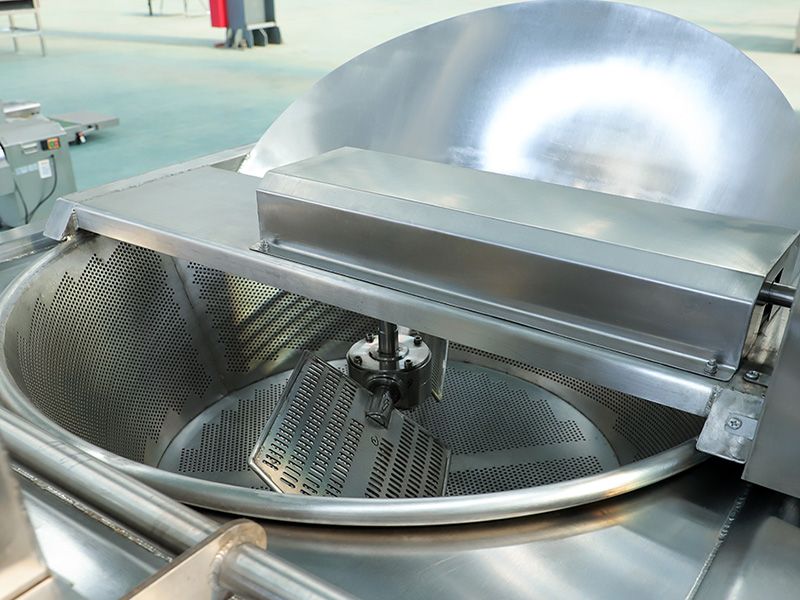

When frying potato chips, the control of temperature and time is crucial. In traditional frying methods, the oil temperature may not be uniform, resulting in some chips being fried too old while others are undercooked. The automatic continuous fryer ensures even temperature distribution in the frying tank by precisely controlling the oil temperature. After entering the frying pool, the chips are continuously turned over by the conveyor belt or roller inside the fryer to ensure that each chip is heated evenly and the frying effect is more stable, thus enhancing the taste and quality of the product.

Enhance product quality and appearance

The continuous potato chips fryer can precisely control the frying time and temperature during operation, so that the potato chips will not absorb oil excessively during the frying process. In this way, it can not only improve the crispness and taste of the chips, but also avoid the appearance of the chips being affected by excessive oil, making the product more beautiful and more acceptable to consumers. High-quality products can enhance the market competitiveness of the brand.

Conclusion

Overall, the application of continuous potato chips fryer in potato chips production can significantly improve production efficiency and product quality. Through automation and precise control, the production line is not only able to handle larger production volumes, but also ensure consistent quality of each chip. As a professional continuous fryer manufacturer, you can always contact lonkia to get an efficient fryer to improve snack quality and increase productivity.