Frozen potato production line is a set of automated processing equipment integrating cleaning, peeling, cutting, blanching, cooling, deep-frying, degreasing, freezing and packaging. For food enterprises that want to put into production frozen French fries, the choice of capacity is directly related to the configuration and price of the entire production line. This article will focus on this core issue, analyze the direct correlation between capacity and price, to help enterprises make more reasonable investment decisions.

Capacity to determine the number of equipment and specifications

Frozen potato production line capacity is generally divided into how many kilograms of potatoes per hour, such as: 300kg/h, 500kg/h, 1000kg/h and so on. The higher the capacity, the higher the specification of the equipment required. For example, the potato cutter machine needs to be equipped with a higher-power motor, and the number of heating tubes and the size of the fryer's tanks need to be expanded in parallel to ensure continuous feeding.

In addition, increasing production capacity usually requires the addition of auxiliary equipment in the pre-processing line (cleaning and peeling) and post-processing line (freezing and packaging), which will further increase the overall cost of the entire production line.

Capacity affects equipment materials and automation

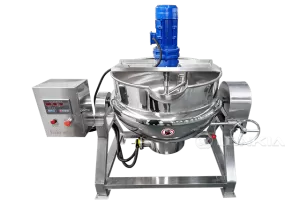

When the production capacity reaches a certain level, in order to ensure stable operation and production efficiency, the material requirements of the equipment will be higher. High-capacity frozen potato production line is often made of thickened stainless steel, more resistant to corrosion and high temperature, longer operating life. At the same time, it will also be configured with more automation control systems, such as PLC touch operation, intelligent temperature control module, automatic cleaning system.

These enhancements not only bring about an increase in production efficiency, but also make the equipment manufacturing costs rise, which is directly reflected in the price.

How to choose the right capacity according to the demand?

When enterprises buy frozen potato production line, they should clarify the required capacity according to the actual factors such as daily processing volume, plant size, sales channels and so on. Do not blindly pursue high capacity and ignore the cost of equipment and efficiency of the use of matching, but also can not be to save costs and choose a low production line resulting in insufficient capacity. Lonkia support for customized production lines, according to the customer's production target to provide the most appropriate equipment models and solutions to help customers with a reasonable budget to achieve the highest capacity and efficiency.

In summary, there is a direct and strong correlation between the frozen French fries production line price and its capacity. The larger the capacity, the higher the requirements for equipment performance, materials, automation, and the price goes up. Enterprises in the investment equipment, be sure to according to their own actual production target scientific selection, to ensure that every investment is worthwhile. If you have further capacity configuration needs or want to know the list of quotations, you can directly contact our technical team to obtain professional advice!