In the modern food processing process, peeling is an important link. Steam peelers have been widely used because of their high efficiency and environmental protection. As a leading equipment manufacturer, Zhucheng Longyuan Machinery will introduce you in detail the working principle and advantages of steam peelers, as well as how steam peelers can peel fruits and vegetables?

Working principle of steam peelers

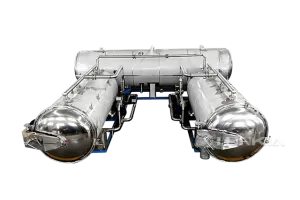

The steam peeler uses high-temperature and high-pressure steam to quickly soften the skin of fruits and vegetables, and then removes the skin by mechanical or hydraulic means. Its working process is as follows:

- Material pretreatment The fruits and vegetables to be peeled are first pretreated, usually including washing and grading, to ensure that the materials entering the steam peeler are clean and uniform in size.

- Steam heating The pretreated materials enter the steam chamber and are quickly heated in a high-temperature and high-pressure steam environment. The temperature of the steam is usually above 150°C. Through the action of high-pressure steam, the connection between the skin and the flesh of fruits and vegetables becomes loose.

- Cooling The heated materials quickly enter the cooling zone, and the surface temperature of fruits and vegetables is suddenly reduced by spraying or soaking. Due to the effect of thermal expansion and contraction, the skin will separate from the flesh, forming a significant separation effect.

- Mechanical peeling After mechanical peeling and cooling, the fruits and vegetables are passed through a rotating brush or spray device to remove the loose skin. This process is efficient and does not damage the flesh, ensuring the integrity and beauty of the fruits and vegetables.

- Washing and discharge The peeled fruits and vegetables are washed again to remove the remaining skin and impurities, and then enter the next process through a conveyor belt.

🍠 Example: Steam Peeling Potatoes and Taro

Potatoes: When potatoes are heated in steam, the skin becomes soft and is no longer tightly connected to the internal flesh. At this time, the skin can be easily removed by a slight external force, and it will not cause too much damage to the flesh, maintaining the integrity and quality of the flesh.

Taro: The skin of taro is relatively hard, but under the action of steam, the skin will also become easy to fall off, greatly improving the efficiency and quality of peeling.

Advantages of steam peeling machine

- The efficient and energy-saving steam peeling machine uses high-temperature and high-pressure steam to complete large-scale peeling work in a short time, improving production efficiency. At the same time, the steam peeling machine has low energy consumption, saving energy costs.

- Protect the pulp Since steam peeling mainly relies on the principle of thermal expansion and contraction, it will not cause mechanical damage to the pulp, ensuring the integrity and beauty of fruits and vegetables, and is suitable for products with high requirements for the appearance of fruits and vegetables.

- Environmentally friendly and hygienic steam peeling machine does not require the use of chemical agents in the peeling process, avoiding chemical residues and ensuring the safety of food. At the same time, the cleaning process of the steam peeling machine is simple, easy to maintain and clean, and meets the hygiene standards of food processing.

- Widely applicable steam peeling machine is suitable for peeling a variety of fruits and vegetables, such as potatoes, carrots, beets, apples, peaches, etc. Whether it is root vegetables or fruit products, the steam peeling machine can efficiently complete the peeling task.

- Zhucheng Longyuan Machinery's steam peeling machine fully considers the precise control of factors such as steam temperature, processing time and pressure in its design to ensure that materials of different types and sizes can achieve ideal peeling effects.

- This peeling method in food processing has many advantages. It not only has high peeling efficiency and can meet the needs of large-scale production, but also can minimize the loss of pulp and improve the utilization rate of raw materials. At the same time, due to the reduction of the use of chemical substances, it is more in line with the requirements of food safety and hygiene.

Steam peeler machine has become an indispensable equipment in the modern food processing industry with its high efficiency, energy saving and environmental protection. Zhucheng Longyuan Machinery is committed to providing customers with advanced steam peeling solutions to help companies improve production efficiency and ensure product quality. If you have more needs or questions about steam peeling machine, please visit Zhucheng Longyuan Machinery official website or contact our sales team. We will wholeheartedly provide you with the best service and solutions.