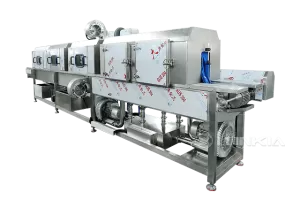

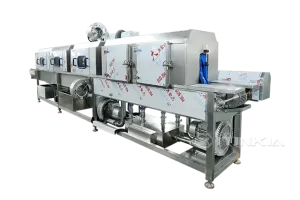

In modern industrial production, the efficiency of cleaning equipment directly affects the smoothness of the entire production process. Industrial basket washer as a kind of efficient automation equipment, through its intelligent and efficient cleaning ability, for the factory to improve productivity plays an important role. In this article, we will discuss in detail how the plastic basket washing machine can improve the productivity of factories through a number of aspects.

Increased cleaning efficiency

Industrial basket washers can quickly and thoroughly clean plastic baskets used in the production process, reducing cleaning time. The equipment utilizes a high-pressure water flow and temperature control system to ensure that each basket is cleaned efficiently, greatly speeding up the cleaning session. This efficient cleaning capability allows the plant to complete cleaning tasks in a shorter period of time, thereby shortening the production cycle, allowing the production line to operate more efficiently and ensuring production continuity.

Ensure cleaning quality and improve product quality

The quality of cleaning has a direct impact on the quality of the product, especially in areas such as food processing industries, where cleanliness is required. Industrial basket washers are able to ensure the cleanliness of each plastic basket through precise water flow control and spray technology, avoiding the uneven and incomplete problems associated with manual cleaning. The efficient cleaning performance of the machine helps to ensure that the production process is not contaminated, which improves the quality of the final product and thus enhances the market competitiveness of the enterprise.

Improved equipment stability and reduced downtime

The industrial basket washer is equipped with an intelligent monitoring and auto-diagnostic system that can detect the working status of the equipment in real time. Once an abnormality occurs, the system will issue an alarm in time, facilitating quick repair and maintenance. This intelligent equipment management greatly reduces the frequency of equipment failures, ensures efficient operation of the production line, and avoids production losses due to downtime. Stable equipment operation improves overall production efficiency and guarantees a seamless production process.

Enhance the automation level of the production line

The application of the basket washersin the production line makes the cleaning process highly automated and reduces the reliance on manual intervention. The equipment is able to automatically adjust the parameters according to different cleaning needs, such as water temperature, water pressure, cleaning time, etc., to provide flexible and efficient cleaning services. The automated production process improves the productivity and production capacity of the factory, and also simplifies the production management, making the whole production process smoother and more efficient.

By improving cleaning efficiency, ensuring cleaning quality, reducing labor costs, improving equipment stability, and enhancing production line automation, the industrial basket washer greatly enhance factory productivity. This efficient and stable cleaning equipment can help factories achieve faster production cycles, higher product quality and lower operating costs, enabling enterprises to occupy a favorable position in the fierce market competition. With the continuous development of technology, the plastic basket washing machine will continue to play an important role in improving factory productivity.