In modern meat processing, meat injector machines are widely used to enhance the flavor and quality of meat. As one of the core components, the design of injection needles directly determines the uniformity, depth and efficiency of brine injection. Therefore, optimizing the needle structure is not only a key step to improve product quality, but also relates to the stability and consistency of the entire production process.

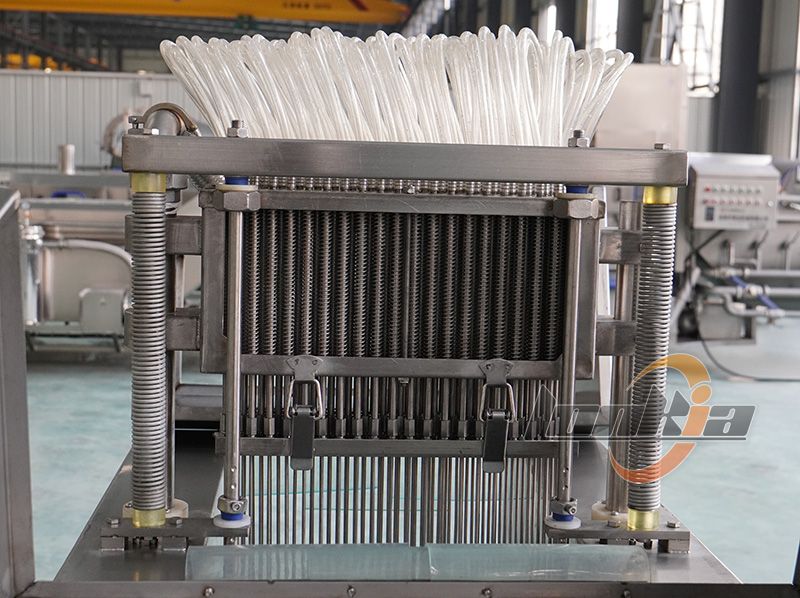

Multi-needle layout for precise injection

High-quality meat injector machines are usually equipped with a multi-needle system. A scientifically arranged array of needles ensures that the brine is evenly distributed within the meat, avoiding dead spots or localized under-marination. This design not only improves flavor consistency, but also helps to shorten marination times and increase productivity.

Lonkia offers a wide range of standard needle count configurations, with common sizes including 48, 80, 120 and 240 needles, for different production volumes and injection densities. Lonkia also supports the customization of needle counts according to the type of product and production needs of the customer, ensuring that every brine saline injection machine achieves optimal injection results.

Precise sizing for injection stability

The size of the needle aperture directly affects the speed and control of the meat injector machine. Lonkia's standard injection needles are available in 3mm and 4mm sizes, which are suitable for different types of meat. 3mm needles are suitable for tender meat such as chicken and fish, which allows for softer and more even injections, while 4mm needles are better suited for products with tighter fibers such as beef and pork, ensuring that the brine is injected in a consistent and even manner. The 4mm needle is more suitable for beef, pork and other products with a tighter fibrous structure, ensuring that the saline can penetrate deeper into the tissue.

Anti-clogging needles for continuous production

To cope with long hours of continuous injection, the Lonkia brine injector needles have an anti-clogging design, which is compact, easy to disassemble and clean, and reduces the problem of meat sludge clogging or brine deposits. The needles are made of food-grade stainless steel, which is corrosion-resistant, mechanically strong, and resistant to deformation and breakage, ensuring that the equipment can continue to operate stably under high-intensity industrial conditions.

Customizable to meet a wide range of needs

In addition to the standard models, Lonkia offers customized configurations of needle sizes and quantities according to the type of product, the injection density and the structure of the meat. Whether it's injecting a highly viscous marinade or precisely injecting a fine-fibered meat, Lonkia has the right needle solution to help customers improve product consistency and process efficiency.

In short, needles are more than just a component of meat injector machine - they determine the depth and breadth of the injection process. From the number and size of needles, to materials and anti-clogging designs, Lonkia is committed to creating more accurate, efficient and stable injection systems to provide reliable injection solutions for meat companies. If you're concerned about the precision and effectiveness of your brine injection, Lonkia's industrial brine injectors are the ideal choice.