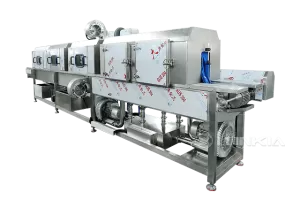

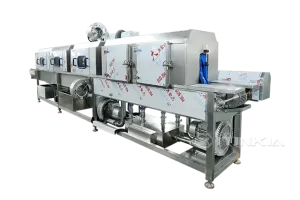

With the growth of market demand and consumers' attention to food safety, the cleaning process of parsley and other vegetables has gradually shifted from manual operation to automated mechanical equipment. As a modern production equipment, the parsley washing line is widely used in the food processing field by virtue of its efficient cleaning ability. This paper will discuss how to improve the cleaning efficiency of this type of equipment.

Combination of multiple cleaning technologies

Parsley washing lines usually combine multiple cleaning technologies, such as water spraying, bubble washing and vibration leaching. The water jet system removes soil, impurities and pesticide residues from the surface of the parsnips quickly and uniformly. Bubble technology, on the other hand, by generating bubbles and vegetable surface friction, making the cleaning effect more thorough, especially in cleaning the leaves, can minimize the damage.

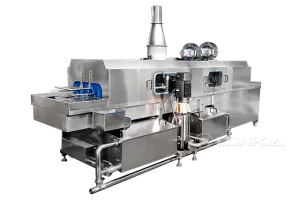

Application of vibratory leaching system

After the cleaning is completed, the vibration leaching system plays a key role. Vibratory draining can not only quickly remove excess water on the surface of parsley, but also maintain the integrity of the appearance of the vegetables, to avoid unnecessary waste caused by excessive accumulation of water. By precisely controlling the frequency and amplitude of vibration, the draining efficiency is greatly improved, reducing the time and cost of subsequent operations.

Efficient conveying and circulation system

The conveying system in the vegetable washing line usually adopts automatic control, which can adjust the speed according to the production demand to ensure that each batch of parsley can be washed in the best time. Together with a highly efficient water circulation system, the efficiency of water use is maximized, reducing resource waste and ensuring continuous efficient operation.

With the above technologies, the parsley vegetable washing line not only improves cleaning efficiency, but also ensures uniformity of cleaning results and the integrity of the vegetables. The combination of these innovations and technologies makes modern washing equipment an indispensable part of the food processing industry.