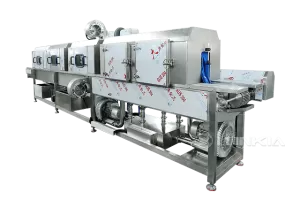

Hygiene standards are crucial in the modern poultry processing industry. Poultry products need to meet strict food safety requirements to ensure that the final product is not contaminated. The poultry crate washer as an automated cleaning equipment, in improving the hygiene standards of the processing plant plays an indispensable role. In this article, we will introduce in detail the working principle of the chicken crate washing machine and how it can effectively improve the hygiene standard of chicken processing.

Efficient decontamination to prevent cross-contamination

Chicken cages are prone to accumulate blood, feathers, feces and other pollutants in the course of use, which not only affect hygiene, but also may become a breeding source for bacteria and germs. Poultry crate washer can completely remove these pollutants through high-pressure spraying and water circulation system. The high-temperature water flow and powerful spray nozzles during the cleaning process ensure that the surface of each chicken coop is thoroughly cleaned, avoiding the problems of omission and unevenness that may occur during manual cleaning.

Improved cleaning consistency

Traditional manual cleaning methods are susceptible to operator skill differences and work fatigue, resulting in inconsistent cleaning results. The chicken crate washing machine, through automated design, can ensure that each cleaning reaches the same standard, to ensure the consistency of the cleaning effect. By setting a fixed cleaning time, pressure and water temperature, the chicken coop cleaner is able to maintain stable performance in different working environments and meet strict hygiene requirements.

Preventing bacterial cross-contamination

The poultry crate washer not only cleans the surface dirt, but also effectively reduces the cross contamination of bacteria. During the process of chicken cage cleaning, the water flow and high-temperature sterilization function of the machine can effectively kill the bacteria left on the chicken cages, ensuring that each cage is completely clean when it enters the next production process. With the expansion of production scale, the use of chicken cage washing machine can significantly reduce the risk of cross-infection, to ensure that the food processing process is not contaminated by microorganisms.

In summary, poultry crate washers not only improve hygiene levels in chicken processing plants, they also effectively avoid cross contamination and improve the consistency of cleaning results. These features make the chicken cage cleaning machine become an indispensable equipment in the modern poultry processing process, to help enterprises meet the more stringent food safety requirements, to provide consumers with more hygienic and healthy chicken products.