When investing in a French fries processing line, it is crucial to choose a line that fits your factory's budget. French fries production line has various configurations, and different equipment and technical requirements will directly affect its price. Therefore, how to choose the right machine according to the budget scientifically? In this article, we will analyze the core components, functional configurations and operating costs of a production line in detail to help companies make informed decisions.

Understanding the core components of French fries production line

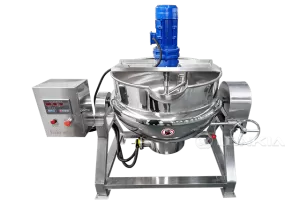

French fries processing line usually includes raw material cleaning, cutting, blanching, cooling, frying, degreasing, cooling, quick-freezing, packaging and other links. The equipment in each segment plays a vital role in the production process, so when choosing a line based on your budget, decide if certain additional features are needed based on actual demand.

For example, there are various options for cleaning and peeling equipment. If the budget is low, basic manual cleaning equipment can be chosen; while high-end fully automatic cleaning and peeling machines are suitable for production needs with higher budgets. For the frying section, different types of fryers (e.g., batch and continuous) will also have an impact on the budget, with continuous fryers usually being more efficient, but with a corresponding increase in price.

Choose the right French fries processing line based on the level of automation

The level of automation has a direct impact on equipment costs and labor expenses. French fries making machine with a high degree of automation is more efficient and more consistent, but the purchase cost is relatively high. For companies with tight budgets, they can prioritize the automation of key processes and upgrade the rest with semi-automatic control. Lonkia's production lines support a wide range of solutions, from semi-automatic to fully automatic, and can be customized according to customer requirements.

Considering production capacity and budget

Enterprises should match the appropriate French fries making machine production capacity according to their daily output demand to avoid over-investment. By rationally planning the number of equipment and the pace of the production line, you can ensure production efficiency and product quality without exceeding your budget.

Lonkia has a wealth of experience in project implementation, we customize the most suitable production line for our customers, to ensure that every penny is well spent, so as to maximize the benefits of investment. We know that it is not the most expensive that is the best, but the most appropriate to create the greatest value.

In conclusion, when choosing a French fries processing line, you need to consider the core functions of the equipment, the degree of automation, and production capacity, etc. Lonkia has always been committed to providing customers with cost-effective food processing equipment solutions, if you are looking for a French fries production line to suit your budget, welcome to consult with Lonkia at any time, and we will provide you with one-on-one professional customized solutions.