As a crucial piece of equipment in meat processing, industrial smoker ovens not only enhance the flavor of the product, but also increase productivity. There are several factors to consider when choosing an industrial smoker that is right for your business, and this article will provide you with a practical guide to buying an industrial smoker.

Industrial smoker oven capacity and size

The first thing to consider is the capacity of the smoking meat machine. Industrial smokers usually come in different capacity ranges, from a few hundred kilograms to several tons. The choice needs to be based on your production needs to determine the right size. If your production volume is large, choosing a smoker with a larger capacity will ensure continuity of production and avoid frequent operations and downtime.

Temperature control system

Temperature control system is one of the core of smoke oven machine. Precise temperature control ensures that the temperature of the meat remains stable during processing, thus ensuring consistent quality from batch to batch. Modern industrial smokers are usually equipped with an automatic temperature control system, which monitors temperature changes in real time and makes adjustments. Choosing a machine with a high-precision temperature control system can effectively reduce human errors and improve production efficiency and quality.

Smoke generation and distribution system

The uniformity of smoke generation and distribution is the key to the smoking effect. A good smoke oven machine should be equipped with advanced smoke generation device, through a unique smoke distribution system to ensure that the smoke circulates evenly in the oven. This not only contributes to the flavor of the meat, but also ensures that each piece of meat absorbs the aroma of the smoke evenly. When choosing, it's a good idea to focus on whether the equipment has an adjustable smoke intensity and distribution design to accommodate different products.

Degree of automation

Modern industrial smoker ovens are becoming more and more automated. Fully automated smokers are capable of intelligent control in heating, smoke generation, humidity regulation, etc., which greatly reduces manual intervention and improves production efficiency. If you want to reduce manual operation and improve efficiency in the production process, you can choose equipment with a higher level of automation.

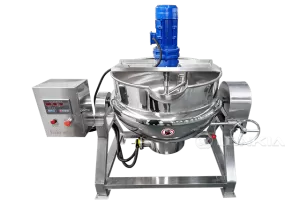

Durability and material

The durability of smoking meat machine is directly related to the service life of the equipment and maintenance frequency. When choosing, you should focus on the material of the equipment, such as stainless steel, which not only has higher corrosion resistance and oxidation resistance, but also easy to clean, suitable for long time and high intensity use. In addition, the thickness and sealing of the furnace body are also important factors to ensure the stable operation of the smoker for a long time.

Conclusion

Choosing the right industrial smoker oven not only improves productivity, but also enhances the quality of the product. Considering factors such as capacity, temperature control system, smoke distribution, degree of automation, and durability during the selection process will help you make an informed decision and ensure the equipment meets your production needs.