Potato chips are a globally popular snack, and setting up an efficient potato chips processing line is crucial for manufacturers looking to enter or expand in this industry. However, choosing the right equipment requires careful consideration of various factors, including production capacity, automation level, quality standards, and budget. In this article, we will guide you through the key aspects to consider when selecting the best potato chips production line for your business.

Determine Your Production Capacity

The first step in choosing the right potato chips processing line is to determine your production scale. Are you targeting a small-scale startup, a mid-sized business, or a large-scale factory? LONKIA Machinery offers solutions for all capacities:

- Small-scale production: 30–100 kg/h

- Medium-scale production: 100–500 kg/h

- Large-scale production: 500+ kg/h

Choosing the right capacity ensures efficient production while avoiding unnecessary operational costs.

Decide Between Automatic and Semi-Automatic Lines

There are automatic and semi-automatic potato chips processing lines available. The right choice depends on labor availability, budget, and desired efficiency.

- Automatic processing lines: Suitable for large-scale production, reducing labor costs and ensuring consistent quality.

- Semi-automatic processing lines: Ideal for small to medium businesses with a limited budget, requiring some manual intervention.

LONKIA Machinery provides customized solutions based on your business needs.

Consider the Key Equipment in the Line

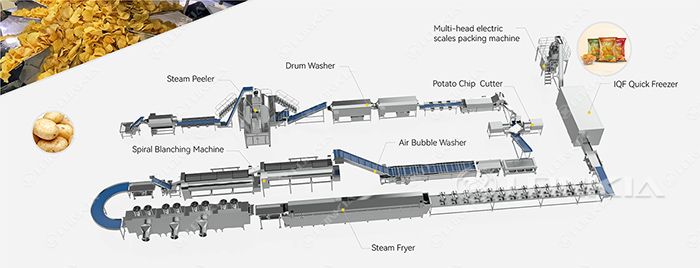

A complete potato chips processing line typically includes the following machines:

- Potato washing & peeling machine – Cleans and removes skin efficiently.

- Cutting machine – Cuts potatoes into uniform slices or strips.

- Blanching machine – Helps maintain color and texture.

- Dehydration machine – Removes excess water before frying.

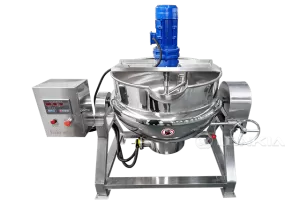

- Frying machine – Ensures crispness and golden color.

- De-oiling machine – Reduces excess oil for a healthier product.

- Seasoning machine – Adds flavors evenly.

- Packaging machine – Ensures product freshness and extended shelf life.

LONKIA Machinery offers fully integrated solutions to streamline the entire production process.

Focus on Quality and Food Safety Standards

When selecting a potato chips processing line, ensure that the equipment meets international food safety standards such as ISO, CE, and HACCP. High-quality stainless steel construction helps maintain hygiene and durability.

LONKIA Machinery's processing lines are designed with food-grade materials to ensure compliance with global industry standards.

Evaluate Energy Efficiency and Cost-Effectiveness

Energy-efficient machines can significantly reduce operational costs. Look for:

- Low energy consumption fryers

- Efficient heat recovery systems

- Automated temperature and oil level controls

LONKIA Machinery's potato chips lines are designed to optimize energy use, providing a cost-effective and environmentally friendly solution.

Look for Customization and After-Sales Support

Every business has unique requirements. A reliable supplier should offer:

- Customization options (e.g., different cutting styles, seasoning systems)

- Installation and training support

- Spare parts availability

- Ongoing technical support

LONKIA Machinery provides tailored solutions and comprehensive after-sales service to ensure smooth operation and maximum productivity.

Conclusion

Choosing the right potato chips processing line is a critical decision that impacts product quality, production efficiency, and profitability. By considering factors such as production capacity, automation level, equipment quality, energy efficiency, and after-sales support, you can invest in the best solution for your business.

At LONKIA Machinery, we offer high-quality, customized potato chips processing lines to meet your specific needs. Contact us today to find the perfect solution for your production goals!