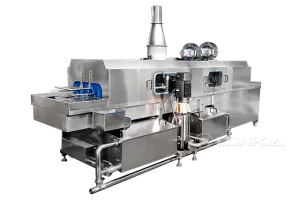

In modern industrial production, plastic tray washing machines, as a kind of efficient cleaning equipment, are widely used in many fields such as food processing, beverage, logistics and so on. In order to adapt to the production needs of different factories, customized plastic pallet washer has become the first choice of more and more enterprises. This article will detail how to customize the industrial tray washing machine according to the actual needs of the factory, to help enterprises improve production efficiency and ensure the hygiene of the production environment.

Customize the cleaning channel according to the tray specifications

Different types of trays vary in size, thickness and material, so when customizing your washer, you'll first need to adjust the width and height of the wash aisle according to the specifications of the pallet, and Lonkia offers a wide range of sizes that can be flexibly adjusted according to the specifications of different trays. Whether it is a standard pallet or a special sized pallet, it ensures consistent cleaning results and avoids incomplete cleaning due to inappropriate channel sizes.

Choose the right cleaning mode

Pallets are used in different environments, and the difficulty and needs of cleaning also differ. For example, the food industry may require thorough cleaning of oil and food residue on the pallet, while the logistics industry may be primarily concerned with removing dirt and dust. When customizing a plastic tray washer, companies can choose from different cleaning modes, such as high-pressure water jetting, brushing, etc. Lonkia's plastic tray washing machines offer a variety of cleaning modes based on a plant's needs, ensuring optimal cleaning results.

Customized heating and drying systems

Certain industries, such as food processing, require very high levels of pallet hygiene. In addition to the regular cleaning functions, it is important to customize the heating and drying systems, as Lonkia's plastic tray washing machines support temperature-controlled heating, which effectively sterilizes the pallets during the cleaning process and accelerates the drying process through a high-temperature drying system. By customizing the heating and drying system, companies can wash and dry pallets in a short period of time to meet the demands of efficient production.

Customized washing process and conveying system

Depending on the layout of the production line and the specific requirements of the factory, the conveyor system of the plastic tray washer can also be customized. Different plants may require different lengths of conveyor belts or rollers for their production lines. Lonkia offers a customized service that allows us to design a conveyor system that is suitable for the pallets according to their conveying direction, speed and other requirements. At the same time, the way the washer is fed and discharged can be optimized to suit the factory's production process, ensuring pallet washing efficiency and ease of operation.

Overall, customized plastic tray washing machines are an important step in improving productivity and ensuring hygiene and safety, and Lonkia offers customized plastic pallet washers that can be flexibly adapted to the needs of different factories in terms of cleaning lanes, cleaning modes, heating and drying systems, and conveyor systems. By cooperating with Lonkia, companies can obtain customized cleaning solutions to improve production line efficiency, reduce production costs and improve product quality.