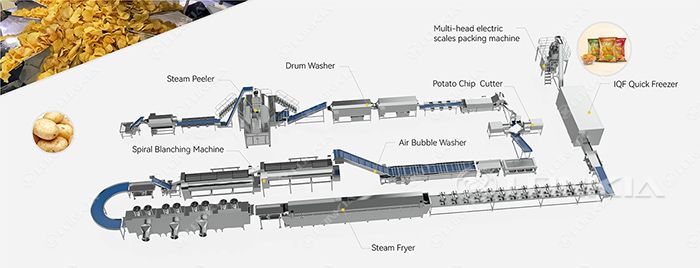

The demand for crispy, high-quality potato chips continues to grow, making efficiency in production more critical than ever. An optimized potato chips manufacturing process not only boosts output but also reduces waste, cuts costs, and ensures consistent product quality. Here are key strategies to enhance efficiency in your potato chips production line.

Optimize Raw Material Handling

The quality of your raw potatoes significantly impacts the final product. Efficient sourcing, handling, and storage can reduce waste and ensure consistency in chip texture and flavor.

✅ Best Practices:

- Use automated sorting and grading systems to eliminate defective potatoes early.

- Maintain proper storage conditions to prevent sprouting and moisture loss.

- Implement a continuous washing and peeling system to speed up the process.

Upgrade to High-Efficiency Slicing and Blanching Machines

Uniform slicing and proper blanching are crucial for achieving consistent chip texture and appearance. Outdated or inefficient equipment can lead to uneven cooking, excess oil absorption, and increased waste.

✅ Best Practices:

- Use high-speed slicing machines for precision cuts and minimal product loss.

- Implement a blanching machine to remove excess starch and reduce frying time.

- Adjust slicing thickness according to the desired chip variety to optimize yield.

Improve Frying Efficiency

The frying process is one of the most energy-intensive steps in potato chips production. Optimizing this stage can lead to reduced oil consumption, lower energy costs, and improved product quality.

✅ Best Practices:

- Use a continuous frying system with temperature control to ensure even frying.

- Regularly filter and replace frying oil to maintain quality and prevent rancidity.

- Invest in an energy-efficient fryer to reduce heat loss and optimize fuel usage.

Enhance Drying and De-Oiling Processes

Excess oil in chips not only affects taste but also shortens shelf life. Proper drying and de-oiling techniques improve texture while maintaining a healthier product.

✅ Best Practices:

- Use centrifugal de-oiling machines to remove excess oil effectively.

- Ensure proper airflow and ventilation in drying systems to prevent sogginess.

- Regularly clean de-oiling components to maintain peak performance.

Automate Packaging and Quality Control

Packaging is the final step, and inefficiencies here can lead to delays, product contamination, and increased labor costs. Automation ensures faster, more accurate packaging while maintaining freshness.

✅ Best Practices:

- Use weighing and filling machines to ensure consistent portioning.

- Implement automated sealing and nitrogen flushing to extend shelf life.

- Integrate AI-driven quality control systems to detect defects and remove undercooked or burnt chips.

Implement Smart Production Monitoring

Modern manufacturing benefits from real-time data tracking and analytics to improve efficiency and minimize downtime.

✅ Best Practices:

- Install IoT-based sensors to monitor temperature, oil quality, and equipment performance.

- Use predictive maintenance to prevent machine failures before they occur.

- Optimize production scheduling to reduce bottlenecks and maximize output.

Conclusion

Improving efficiency in your potato chips manufacturing process requires a combination of modern technology, process optimization, and preventive maintenance. By upgrading equipment, automating critical stages, and implementing smart monitoring systems, manufacturers can increase production output, reduce costs, and ensure high product quality.

At LONKIA Machinery, we provide cutting-edge potato chips processing solutions designed for efficiency and reliability. Contact us today to learn how we can help optimize your production line!