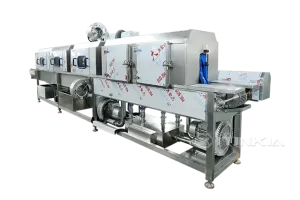

The parsley vegetable cleaning line is a highly efficient automated machine that can help improve the efficiency and quality of vegetable washing. Regular maintenance is essential to ensure that the machine operates properly for a long period of time. In this article, we'll explain how to effectively maintain your vegetable washing line to extend its lifespan.

Regular cleaning of parsley vegetable cleaning line

Cleaning is the most basic and important step in vegetable washing line maintenance. When the machine is in use, dirt, impurities and residual moisture tend to accumulate on various parts, especially on the washing tank, nozzle, conveyor belt and other locations. Therefore, it is important to thoroughly clean the machine after each day's use, especially the cleaning area and the water hose system. Regularly check whether the nozzle is clogged or not, and make sure the water flow is smooth so as not to affect the cleaning effect.

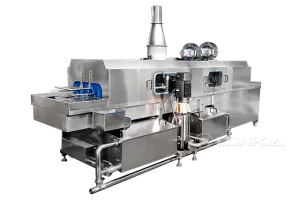

Check the water pump and motor

The water pump and motor of the parsley vegetable cleaning line are the core components for its normal operation. Regularly check the working condition of the water pump to ensure that there is no leakage or abnormal noise. If the water pump is found to be abnormal, it should be replaced or repaired in time. The motor part also needs to be checked regularly to see if the wire connections are firm to avoid downtime due to electrical faults.

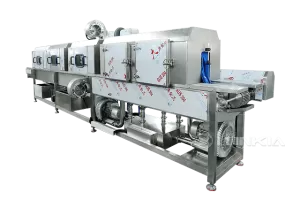

Maintaining the conveyor belt and rollers

The conveyor belt is an important part of the conveyor in the parsley washing line. Regularly check its tension and wear and tear to ensure the smooth operation of the conveyor belt. Conveyor belts that are badly worn need to be replaced promptly. In addition, rollers and other moving parts need to be checked regularly to ensure they are not loose or damaged. If any abnormalities are found, they should be adjusted or replaced immediately.

Replacing the filtration system

To ensure clean water, the filtration system needs to be replaced regularly. A filtration system removes impurities and dirt from the water, preventing these substances from re-contaminating your vegetables. Check the filter every so often to make sure it is not overly clogged and maintains good filtration.

Pay attention to component lubrication

Moving parts of the machine, such as bearings and gears, need to be lubricated regularly to minimize friction and wear. The lubricant should be chosen according to the manufacturer's recommendations, and should be checked and replenished regularly to ensure that the components can run smoothly.

In conclusion, regular maintenance and inspection is the key to ensuring that your parsley vegetable cleaning line runs properly for a long time. By keeping it clean, inspecting key components and replacing damaged parts in a timely manner, you can greatly extend the life of your machine and increase productivity. With careful maintenance, your parsley washing line will always be as good as new, helping your production line to operate efficiently.