In the food processing industry, French fries have become a popular product due to its wide market demand. To efficiently produce frozen French fries with stable quality, a high-performance frozen French fries processing line is the key. By rationally configuring equipment and optimizing operating procedures, companies can significantly increase production capacity and reduce operating costs.

Compact overall process layout

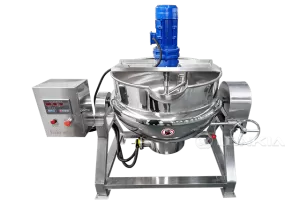

An efficient frozen French fries processing line usually includes cleaning and peeling, cutting, blanching, frying, cooling, freezing and packaging. The smooth connection between each step has a direct impact on the overall efficiency of the operation. The modular design of Lonkia's frozen French fries manufacturing machine ensures smooth transitions between processes, avoiding material stagnation and line clogging, thus dramatically increasing throughput.

Automated control systems for operational efficiency

Increased production capacity can only be achieved with the support of automation technology. Modern frozen French fries processing lines are equipped with intelligent control systems that precisely control key parameters such as cutting size, frying time and temperature. Pre-programmed to make it easy for operators to manage the line and reduce human error, Lonkia has introduced an advanced PLC control system to make the manufacturing process easier and more efficient to operate.

Control of frozen French fries production line operating parameters

The operating parameters of the production line, such as temperature, speed and time, have a direct impact on the yield. Taking cooling and freezing as an example, proper adjustment of cooling and freezing time and temperature can ensure that the fries are frozen optimally in the shortest possible time, avoiding over-freezing or uneven freezing, and guaranteeing consistent quality from batch to batch. Lonkia's frozen French fries production line supports intelligent control, which allows real-time monitoring and adjusting of these parameters to ensure the maximum efficiency of each production.

Regular maintenance and servicing

Even state-of-the-art frozen French fries processing lines require regular maintenance to keep them operating efficiently, and Lonkia's equipment is designed with ease of maintenance in mind, simplifying routine maintenance. Regular cleaning of the equipment, replacement of worn parts and troubleshooting will help extend the life of the frozen French fries making machine and avoid production downtime due to equipment failure. By keeping your line in optimal working condition, you can avoid unnecessary production downtime and ensure continuous and efficient production.

Overall, a high-performance frozen French fries processing line is an essential part of any daily production of frozen fries, and Lonkia offers a complete line solution that not only focuses on efficiency and consistency, but also ensures that each batch of product is of the highest quality to meet market demand and increase brand value.