In industries such as food processing, pharmaceuticals, logistics, and manufacturing, maintaining clean pallets is essential for hygiene, regulatory compliance, and operational efficiency. However, an inefficient pallet washing process can lead to high water consumption, energy waste, increased labor costs, and inconsistent cleaning results.

By optimizing your pallet washing process, businesses can enhance productivity, cost-effectiveness, and hygiene standards while reducing environmental impact. This article outlines the best strategies to achieve maximum efficiency in pallet washing.

🔹 Assess Your Pallet Contamination Levels

✅ Why It Matters:

Not all pallets require the same level of cleaning. Some may have light dust, while others may be covered in grease, chemicals, or food residues.

🔧 Optimization Strategy:

✔ Sort pallets based on contamination level – Use pre-wash cycles for heavily soiled pallets to reduce the main washing cycle time.

✔ Use targeted cleaning programs – Adjust washing duration and intensity based on dirt levels.

✔ Schedule frequent cleaning – Regular washing prevents excessive buildup, reducing deep-cleaning requirements.

🔹 Optimize Water Temperature and Pressure

✅ Why It Matters:

Temperature and pressure significantly impact the removal of grease, oils, and bacteria from pallets.

🔧 Optimization Strategy:

✔ Use hot water (60-85°C / 140-185°F) for better grease and residue removal.

✔ Adjust pressure levels – High pressure removes tough stains but may damage fragile pallets.

✔ Optimize water flow – Use high-efficiency spray nozzles to enhance cleaning effectiveness while reducing water usage.

🔹 Example:

- Lightly soiled pallets – 50°C, low-pressure wash

- Greasy or food-contaminated pallets – 75-85°C, high-pressure wash

🔹 Choose the Right Detergents and Cleaning Agents

✅ Why It Matters:

Using the wrong detergent can lead to inefficient cleaning, residue buildup, and excessive chemical waste.

🔧 Optimization Strategy:

✔ Use detergents compatible with pallet materials (plastic, wood, or metal).

✔ Adjust chemical concentration – Avoid excessive detergent use, which leads to higher costs and potential residue issues.

✔ Incorporate automated dosing systems – Ensures consistent detergent use and prevents overuse.

🔹 Example:

- Enzyme-based detergents – Ideal for organic residues at moderate temperatures.

- Alkaline cleaners – Effective for removing oils and greases.

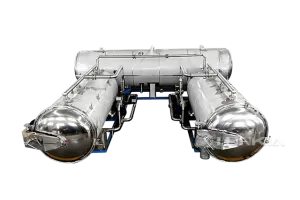

🔹 Implement Water and Energy Conservation Strategies

✅ Why It Matters:

Washing pallets can be water- and energy-intensive, leading to higher operational costs.

🔧 Optimization Strategy:

✔ Use a water filtration and recycling system to reuse rinse water.

✔ Optimize heat recovery systems to recycle energy from hot water.

✔ Schedule full wash loads instead of running half-empty cycles to maximize efficiency.

🔹 Example:

A water recycling system can reduce water usage by up to 50%, making the process more sustainable and cost-effective.

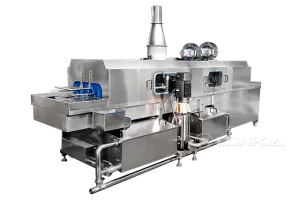

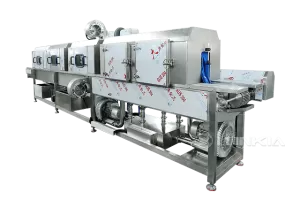

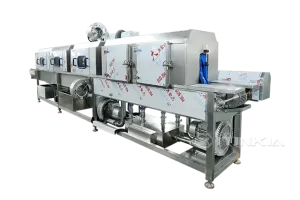

🔹 Automate the Pallet Washing Process

✅ Why It Matters:

Manual pallet washing is time-consuming, labor-intensive, and inconsistent.

🔧 Optimization Strategy:

✔ Upgrade to an automated pallet washer – Reduces manual effort and increases throughput.

✔ Use programmable washing cycles – Customize temperature, pressure, and duration based on contamination levels.

✔ Integrate conveyorized washing systems – Ensures continuous pallet cleaning for high-volume operations.

🔹 Example:

Automated pallet washers can process hundreds of pallets per hour, compared to manual washing, which is significantly slower.

🔹 Regular Maintenance to Ensure Consistent Performance

✅ Why It Matters:

A poorly maintained washer can result in clogged nozzles, reduced cleaning effectiveness, and unexpected breakdowns.

🔧 Optimization Strategy:

✔ Regularly clean filters and spray nozzles to prevent blockages.

✔ Inspect heating elements and pumps to maintain temperature control.

✔ Monitor detergent levels and recalibrate dosing systems if necessary.

🔹 Example:

Implementing a weekly maintenance schedule prevents unplanned downtime and improves operational efficiency.

🔹 Monitor and Analyze Washing Performance

✅ Why It Matters:

Tracking washing performance helps identify inefficiencies and areas for improvement.

🔧 Optimization Strategy:

✔ Use digital monitoring systems to track water usage, energy consumption, and cleaning cycles.

✔ Analyze washing cycle reports to optimize settings based on real-time data.

✔ Adjust washing schedules to prevent unnecessary operation during low-demand periods.

🔹 Example:

IoT-enabled pallet washers allow for real-time tracking of cleaning efficiency, helping managers optimize resource usage.

🔹 Conclusion: Achieve Maximum Efficiency in Pallet Washing

Optimizing your pallet washing process helps businesses:

✅ Reduce water, detergent, and energy consumption

✅ Improve cleaning effectiveness and hygiene compliance

✅ Lower labor costs by automating repetitive tasks

✅ Extend pallet lifespan by preventing damage from excessive washing

At LONKIA Machinery, we provide state-of-the-art pallet washing solutions with customizable cycles, automation, and energy-saving features. Contact us today to discover how our high-performance pallet washers can enhance your operations! 🚀