The demand for potato chips continues to rise globally, driven by their popularity as a snack food. To meet this demand efficiently and consistently, food manufacturers need to invest in a modern potato chips processing line. These production lines are designed to streamline the process from raw potatoes to the final packaged product, ensuring high quality, efficiency, and cost-effectiveness.

In this article, we’ll explore the key features you should look for when selecting a modern potato chips processing line for your business.

High-Quality Raw Material Handling

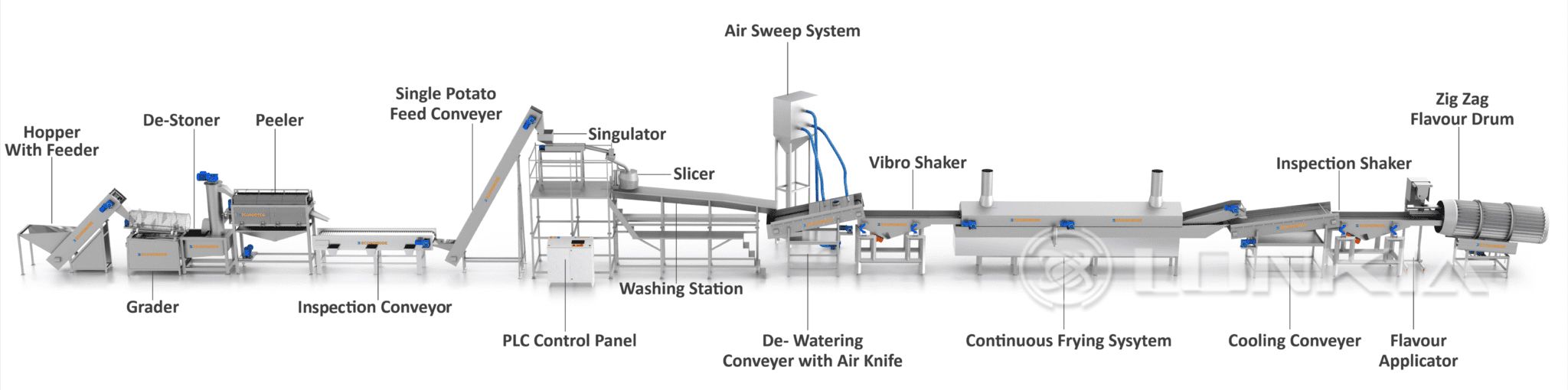

The foundation of a great batch of potato chips starts with high-quality raw potatoes. A modern processing line should include equipment designed for efficient handling of raw materials:

- Potato Sorting and Washing Machines: To ensure uniformity and remove dirt, stones, or other impurities before processing.

- Peeling Machines: High-performance peeling machines are essential for removing potato skins without wasting too much of the potato. Automated peeling technology improves efficiency and consistency.

A high-quality raw material handling system ensures that the potatoes are clean and of consistent quality, laying the groundwork for the entire production process.

Advanced Cutting and Slicing Technology

Achieving the perfect potato chip texture begins with precise and consistent slicing. The cutting machine is a key feature in a modern processing line, offering:

- Uniform Thickness Control: Ensures consistent chip size and cooking quality.

- Flexible Cutting Styles: Some machines allow for customization, including straight cuts, wavy cuts, or crinkle cuts to cater to market demands.

- Minimal Waste: High-efficiency slicers reduce potato waste, maximizing raw material usage.

By selecting equipment with precise slicing capabilities, manufacturers can produce high-quality chips with the right texture and appearance.

Efficient Blanching System

Blanching is a critical step in potato chip production, where the sliced potatoes are briefly immersed in hot water to remove excess starch and preserve the color and texture of the chips. A modern processing line should include:

- Automated Blanching Machines: These machines provide precise control over temperature and timing, ensuring optimal results without overblanching.

- Water Recovery Systems: Systems that reduce water consumption by recycling water used during blanching are key for sustainability and cost savings.

Blanching systems that ensure consistency in starch removal and color preservation play a major role in the final appearance and crispiness of potato chips.

Advanced Frying Technology

The frying process is arguably the most important step in creating delicious, crispy chips. Modern potato chips processing lines are equipped with advanced frying machines that offer:

- Temperature Control: Precise temperature regulation ensures even frying and prevents burning or undercooking.

- Oil Circulation and Filtration: Continuous filtration of the frying oil helps maintain the quality of the chips and extends the life of the oil.

- Oil Reduction Systems: De-oiling machines reduce the excess oil on the chips after frying, making them healthier and more appealing to consumers.

With advanced frying technology, manufacturers can achieve crispy chips with uniform color and texture while optimizing energy and oil usage.

Flavoring and Seasoning Systems

To create the perfect flavor profile for your chips, an efficient seasoning machine is essential. Key features to look for include:

- Uniform Seasoning Application: A high-quality seasoning machine ensures that the right amount of seasoning is applied evenly across each chip.

- Customizable Flavoring Options: Some machines allow for the adjustment of seasoning quantities, allowing you to create different flavor profiles to meet consumer preferences.

- Minimal Seasoning Waste: A well-designed system minimizes the waste of seasoning, ensuring cost efficiency.

Flavoring systems should deliver consistent seasoning with minimal loss to ensure product quality and reduce costs.

Efficient Packaging Solutions

Packaging is crucial to maintaining the freshness and extending the shelf life of potato chips. A modern processing line should include:

- Automatic Packaging Machines: These systems seal the chips in airtight bags to prevent exposure to air and moisture, keeping them crisp and fresh.

- Weighing and Counting Systems: Automated systems ensure accurate portioning and packaging of chips.

- Sustainable Packaging Options: Modern systems often integrate eco-friendly packaging materials to cater to consumer demand for environmentally conscious products.

Efficient packaging systems preserve product freshness and help manufacturers meet distribution demands, while also meeting consumer sustainability preferences.

Energy Efficiency and Sustainability Features

As energy consumption and environmental impact are major concerns in modern food production, it's essential to choose a potato chips processing line that offers energy-efficient features:

- Energy-Efficient Fryers: Frying equipment that reduces oil and energy consumption can lower operational costs while maintaining the quality of the chips.

- Water and Oil Recycling Systems: Recycling water and oil from various stages of production reduces waste and resource consumption.

- Low-Carbon Footprint Design: Machines that are designed to minimize energy usage and emissions contribute to a more sustainable production process.

An energy-efficient and sustainable potato chips processing line not only reduces operational costs but also enhances a brand’s eco-friendly reputation.

Automation and Control Systems

To improve efficiency and reduce human error, look for a processing line with automated control systems that allow for easy monitoring and adjustments:

- Programmable Logic Controllers (PLCs): These allow operators to set parameters, track performance, and adjust settings automatically.

- Real-Time Monitoring: Advanced monitoring systems enable remote troubleshooting and performance tracking, reducing downtime.

- User-Friendly Interfaces: Machines with intuitive control panels make it easier for operators to manage the entire production process.

Automation improves overall efficiency and ensures that the production line operates smoothly with minimal supervision.

Conclusion

When choosing a modern potato chips processing line, it’s important to look for features that enhance efficiency, quality, and sustainability. From raw material handling to precise frying technology and energy-efficient systems, selecting the right processing line can significantly improve product consistency and reduce operational costs.

Investing in a high-quality processing line ensures that your potato chips are consistently of the highest quality, meeting consumer expectations for flavor, texture, and nutrition. Whether you're a small-scale operation or a large manufacturer, these key features will set your production up for success.