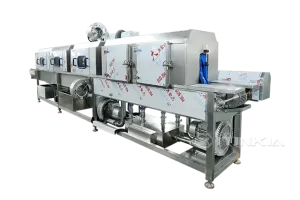

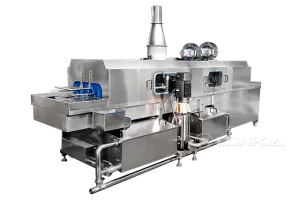

In the poultry processing industry, cleaning poultry cages is an important part of maintaining hygiene and ensuring food safety. The selection of poultry crate washing machine is critical to improving efficiency and reducing labor costs. In this article, we will provide you with a detailed overview of the key features you need to focus on when choosing a crate washing machine.

Degree of automation

Automation is one of the most important factors to consider when choosing poultry crate washers. Most modern cleaning equipment is equipped with an automated control system, which can automatically adjust the cleaning intensity and time according to the degree of cleanliness of the cage. A high degree of automation not only reduces manual intervention, but also ensures the consistency of each cleaning process, thus improving the cleaning effect and avoiding the hygiene hazards that may be brought about by manual operation.

Cleaning capacity of the crate washing machine

Cleaning capacity directly affects the cleaning efficiency, usually through the equipment nozzle pressure, the number of nozzles and water flow rate to judge. An efficient poultry crate washing machine should have powerful water jets that can thoroughly remove stains, feathers and feces from the cage. To ensure effective cleaning, choose a unit with multiple adjustments that can be adjusted for different levels of contamination and cage materials.

Durability and material selection

The durability and longevity of industrial crate washer depends on the material it is made from. High-quality stainless steel is the most commonly used material, which is highly resistant to corrosion and high temperatures, and is able to cope with high-pressure water streams and high-temperature water vapor during the cleaning process. Choosing to use high-quality stainless steel ensures the stability and durability of the machine over the long term, reducing the frequency and cost of repairs.

Water circulation system

A good water circulation system is another key feature of poultry crate washing machines. An efficient water circulation system maximizes the use of wash water, reduces water waste and ensures thorough cleaning. A good water circulation system not only saves operating costs, but also improves the efficiency and economy of the machine. Choosing a water circulation system with filtration and sedimentation will help reduce scale buildup and extend the life of the equipment.

Ease of operation and maintenance

The ease of operation and routine maintenance of the equipment is also a very important consideration. Users should choose those crate cleaners with clear operation panels and intuitive control systems. At the same time, routine cleaning and maintenance of the equipment should be as simple as possible to minimize downtime and repair costs. Quality equipment is often equipped with self-cleaning features to reduce the difficulty of manual maintenance.

When choosing the right poultry crate washing machine, factors such as the degree of automation, cleaning capacity, durability, water circulation system and ease of operation all need to be considered. By choosing high-performance cleaning equipment, you can not only improve efficiency and ensure health and safety, but also reduce maintenance costs in long-term use. We hope that this article will provide you with valuable references when choosing the right crate washing machine.