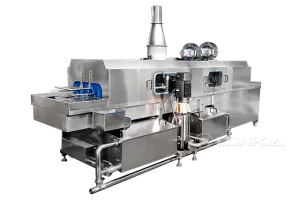

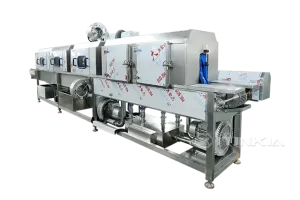

The Lonkia plastic crate washing machine is a highly efficient machine designed for cleaning plastic baskets, widely used in the food, agriculture and logistics industries. The multifunctional cleaning system effectively removes stains and bacteria from plastic baskets, ensuring hygiene and safety. The Lonkia industrial crate washer offers stable performance and flexible configuration options that can be customized to suit different working environments and cleaning needs.

Lonkia plastic crate washing machine component systems

Conveyor system

The conveyor system of the Lonkia industrial crate washer consists of a speed reducer, a chain track, a limit bar, an override bar and an inlet. The speed reducer is precisely designed to ensure the stability and efficiency of the machine, while the chain track guarantees the smooth transportation of the baskets. The limiting bar and overlaying bar ensure that the baskets are kept in the correct position during the cleaning process, preventing sliding or misalignment from affecting the cleaning effect. The inlet is well designed so that plastic baskets of different sizes can enter the washing area smoothly.

Cleaning system

The washing system of the Lonkia plastic crate washer can be set up with several washing sections according to the requirements, including pre-wash, main wash and rinse. The washing system is equipped with a high-performance water pump, which provides a constant water pressure. It is equipped with high efficiency spray nozzles, the number and angle of which have been scientifically calculated to ensure that the wash water fully covers every corner and achieves efficient decontamination. The system can flexibly adjust the cleaning intensity and water speed to cope with different levels of stains.

Electronic control system

The electronic control system is the center of the equipment, responsible for the operation control of the whole machine, Lonkia plastic crate washing machine adopts intelligent control panel, you can freely set the operation mode, cleaning time, conveying speed and other parameters, so as to make the operation more simple, efficient and intelligent. In addition, the electric control system is equipped with overload protection, leakage protection and other safety measures to ensure that the equipment is stable and reliable in the long run.

Air-drying system (on-demand configuration)

The air-drying system adopts the structure of fan and air knife, blowing away the residual moisture on the surface of the container through high-speed airflow. The system can be customized with medium pressure fan to enhance the air drying effect. The arrangement of air knives is optimized to ensure that the airflow evenly covers the surface of the box to achieve fast drying and avoid water residue affecting subsequent use.

Drying system (on-demand configuration)

For users with higher drying needs, an optional drying system is available, which consists of an air pump and a drying electric heater. The air pump provides a stable airflow, while the dry-fired electric heaters heat up the air quickly to achieve deep drying, ensuring that the container reaches a completely dry state in a short period of time. The drying system is suitable for industries that require strict drying results, such as food processing enterprises, to further improve production efficiency.

Summary

The Lonkia plastic crate washing machine offers a complete set of efficient washing, air-drying and drying solutions through its advanced composition system, which can meet the needs of different companies for crate washing. Its multi-stage washing system ensures that dirt is thoroughly removed, while the optional air-drying and drying systems make the machine even more suitable for different application scenarios. Whether it is a food processing plant, a logistics company or an agricultural producer, the Lonkia crate washer is the ideal choice to raise the standard of container cleanliness and optimize production processes.