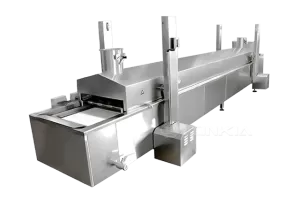

As an important equipment in modern food processing, the structural design of potato fries cutter machine directly affects the quality and productivity of the product. Among the many design elements, the corrugated blade is one of the indispensable core components in the French fry cutting machine. In this article, we'll take a closer look at the role of corrugated blades in cutters to help you understand why this design can significantly improve production results.

Corrugated blades: core component of potato fries cutter machine

In modern French fries cutting machines, the corrugated blades are the key component to achieve neat cuts and enhance the appearance of the product. They are not only sharp, but also have a long service life, making them ideal for high-volume, continuous operations. The corrugated blade creates a unique curved texture compared to traditional straight blades, making fries more visually and tastefully appealing.

Corrugated structure design improves cutting efficiency and aesthetics

The curved edge design of the corrugated blade enables the blade to contact the material more evenly during the cutting process, thus avoiding problems such as broken or shattered strips. This structure not only improves the integrity of the fries, but also makes the cutting process smoother and more fluid. The corrugated angle of the blade is precisely calculated to maintain the three-dimensionality of the cut without affecting the overall structure of the potato, which helps the heat penetrate evenly during subsequent frying.

Blade mounting structure is simple and easy to maintain

Lonkia's potato fries cutter machine is constructed with a quick-release blade holder design, which allows operators to replace or clean the blades in a short period of time. The corrugated blades are fixed by clips or bolts, which is stable and not easy to be shifted and guarantees the cutting precision. In addition, the transmission structure of the blade and the motor is closely matched, which ensures the power output and reduces the risk of failure due to loosening of the structure.

Structural stability enhances cutting consistency

The overall frame of the electric French fry cutter is welded from food-grade stainless steel, and the blade is partially mounted in the middle of the cutting chamber to maintain verticality in the same direction as the material transfer direction. This structure ensures that each potato is stably positioned before it enters the blade. Combined with the balanced force design of the corrugated blade, the final cut fries are highly consistent in length, thickness, and texture, with a high degree of standardization.

Overall, the corrugated blade is not only an important cutting component of the French fry cutting machine, but also the core structure to ensure the uniformity of the shape of the French fries, high cutting efficiency and stable operation of the equipment. By optimizing the structure and upgrading the blade material, Lonkia potato fries cutter machine performs well in the actual use of French fries production line, providing reliable technical support for food processing enterprises.