When choosing the French fry production line, cost is an important factor that every manufacturer must consider. Depending on the level of automation, the price of French fries production line for sale can vary. In this article, we'll explore the price differences between semi-automated and fully-automated production lines, as well as the features of each to help you make an informed purchasing decision.

Features of semi-automatic French fries production line price

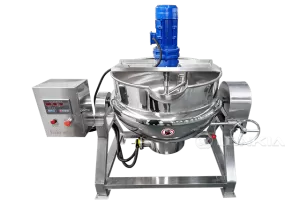

Semi-automated French fry production lines usually rely on manual labor to work with machines to complete the production process. Although it is less automated, it is relatively more economical in terms of price, making it suitable for small factories or startups with limited budgets. Semi-automatic production lines rely on some basic equipment such as potato cutter machines, fryers, seasoning machines and packaging machines with more manual involvement.

Since the automatic French fries making machine configuration is more simplified, it is less expensive and more flexible. The control system of the equipment is relatively simple, mostly push-button control or basic electric control box, without PLC programming or touch screen operation, the overall investment threshold is low. It is suitable for small-scale processing plants with daily output between 500kg and 1000kg. The price varies greatly depending on the configuration, but the overall entry-level solution is suitable for investors with limited budgets or those entering the market for the first time.

Features of fully-automatic French fries production line price

Fully automated French fries production line for sale, on the other hand, adopts more advanced technology and equipment, with a higher degree of automation and almost no need for human intervention. The entire production line is equipped with automated equipment to perform all steps from raw material handling, fries cutting, frying, seasoning to packaging. The main advantages of a fully automated production line are a significant increase in productivity, a reduction in labor costs, and the ability to maintain high throughput while ensuring consistent product quality.

Each stage of french fries maker machine is precisely connected to each other by conveyor belts. This configuration means higher production capacity (up to 2T/h or more) and a larger upfront investment. Although the price is higher than a semi-automatic production line, the advantages in terms of labor savings, efficiency, product consistency and hygiene standards are obvious, and it is more suitable for medium and large enterprises or export-oriented food factories.

Overall, the choice between a semi-automatic or fully-automatic French fries production line for sale depends on the specific needs of the organization, the size of the production and the budget. In addition, Lonkia can provide you with the right solution for your needs and professional advice, customizing a detailed configuration and return on investment analysis.