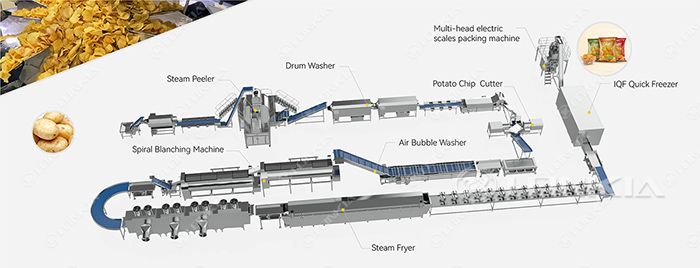

Potato chips are one of the most popular snacks worldwide, loved for their crispiness and rich flavor. The production of high-quality chips requires a well-designed potato chips processing line with efficient machines at each stage. In this guide, we will walk you through the step-by-step process of transforming raw potatoes into crispy, delicious chips using LONKIA Machinery's advanced equipment.

Step 1: Potato Selection & Sorting

The quality of potato chips starts with selecting the right raw materials. High-starch, low-sugar potato varieties like Atlantic, Snowden, or Russet are ideal for chip production. The potatoes are sorted based on size, shape, and quality to ensure uniform frying and consistency.

✅ Recommended Machine: Potato Sorting & Grading Machine

📌 Function: Automatically sorts potatoes by size and removes defective ones.

Step 2: Washing & Peeling

Once sorted, the potatoes must be thoroughly washed to remove dirt and impurities. Peeling is essential to ensure a smooth texture and enhance the final product's appearance.

✅ Recommended Machine: Potato Washing & Peeling Machine

📌 Function: Uses rotating brushes and water spray to clean and peel potatoes efficiently.

Step 3: Slicing & Cutting

After peeling, the potatoes are sliced into thin, uniform pieces to ensure even frying. Some businesses may also choose to produce crinkle-cut or stick-shaped chips for variety.

✅ Recommended Machine: Potato Chips Cutting Machine

📌 Function: Precisely slices potatoes into uniform thickness, ensuring consistent frying.

Step 4: Blanching

Blanching is a crucial step to remove excess starch, prevent oxidation, and improve the chips' texture. The process involves briefly immersing potato slices in hot water (65–85°C).

✅ Recommended Machine: Potato Chips Blanching Machine

📌 Function: Maintains chip color, enhances texture, and reduces oil absorption during frying.

Step 5: Dehydration

Before frying, excess moisture must be removed to prevent oil splattering and ensure crispy chips.

✅ Recommended Machine: Potato Chips Dehydrator Machine

📌 Function: Uses centrifugal force or hot air to remove surface moisture.

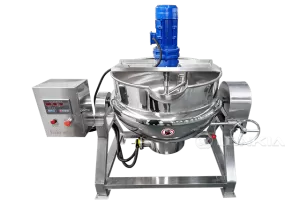

Step 6: Frying

Frying is the most critical step, as it determines the chips' crispiness, color, and taste. The oil temperature is typically maintained between 160–180°C, and the frying time is carefully controlled to achieve a golden-brown color.

✅ Recommended Machine: Automatic Continuous Frying Machine

📌 Function: Ensures uniform frying with precise temperature and oil circulation control.

Step 7: De-oiling

After frying, excess oil must be removed to make the chips healthier and prevent them from becoming greasy.

✅ Recommended Machine: De-oiling Machine

📌 Function: Uses centrifugal force to remove extra oil and improve chip texture.

Step 8: Seasoning

The final step in enhancing the chips' flavor is adding seasonings such as salt, cheese, barbecue, or spicy flavors.

✅ Recommended Machine: Potato Chips Seasoning Machine

📌 Function: Evenly coats chips with seasoning for a consistent taste.

Step 9: Packaging

To maintain freshness and extend shelf life, the chips must be properly packaged in airtight bags.

✅ Recommended Machine: Automatic Packaging Machine

📌 Function: Seals chips in air-tight packaging to prevent moisture and ensure longer shelf life.

Conclusion

Producing high-quality potato chips requires a well-structured production line and high-performance equipment at each stage. From washing and slicing to frying and packaging, LONKIA Machinery offers customized potato chips processing solutions to meet your production needs.

💡 Looking for a complete potato chips production line? Contact LONKIA Machinery today for expert solutions!