In industries such as food processing, pharmaceuticals, logistics, and manufacturing, cross-contamination poses a serious risk to product safety and quality. Reusable pallets are essential for transporting goods, but without proper cleaning, they can become a breeding ground for bacteria, mold, and harmful residues.

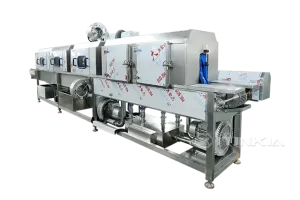

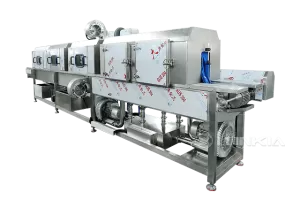

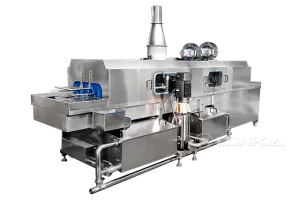

A pallet washing machine is a crucial solution for maintaining hygiene standards and preventing contamination. By automating the cleaning process, these machines remove dirt, bacteria, and allergens, ensuring that pallets meet strict industry safety regulations. In this article, we will explore how pallet washing machines help prevent cross-contamination and why they are essential for businesses that rely on clean and sanitized pallets.

🔹 What Is Cross-Contamination and Why Is It Dangerous?

Cross-contamination occurs when bacteria, allergens, chemicals, or other harmful substances are transferred from one surface to another. In the context of pallets, this can happen in several ways:

🔸 Food Industry: Contaminated pallets can transfer salmonella, E. coli, and listeria to fresh produce, meat, or packaged goods.

🔸 Pharmaceutical Industry: Improperly cleaned pallets can spread chemical residues or biological contaminants between products.

🔸 Logistics & Warehousing: Pallets used for different product categories (e.g., food, chemicals, and raw materials) can transfer harmful substances if not properly sanitized.

Without an effective washing and sanitization process, businesses risk product recalls, regulatory fines, and damaged reputations due to contamination-related issues.

🔹 How Pallet Washing Machines Prevent Cross-Contamination

A pallet washing machine is designed to efficiently clean and disinfect pallets using high-pressure water jets, detergents, and hot water. Here’s how it helps prevent contamination:

✅ Removes Dirt, Bacteria, and Residues

✔ High-pressure nozzles effectively remove organic matter, dust, and food particles.

✔ Heated water and detergents kill harmful bacteria and viruses.

✔ Rinsing cycles eliminate chemical residues from previous use.

🔹 Why It Matters?

Manually scrubbing pallets often misses hidden contaminants, while automated washing ensures a deep and thorough clean.

✅ Eliminates Cross-Contact Between Different Product Categories

✔ Pallet washers allow dedicated cleaning cycles for different product types.

✔ Separate washing settings ensure pallets used for chemicals don’t mix with food pallets.

🔹 Why It Matters?

Cross-contact between incompatible products (e.g., food and industrial chemicals) can lead to serious safety hazards.

✅ Consistent and Standardized Cleaning Process

✔ Automatic washers maintain consistent water temperature and pressure for reliable cleaning.

✔ Sensors and programmable settings ensure each pallet meets industry hygiene standards.

🔹 Why It Matters?

Manual washing can be inconsistent, leading to missed spots and potential contamination.

✅ Reduces Human Error in Cleaning

✔ Eliminates variation in cleaning quality caused by manual labor.

✔ Reduces risk of workers missing critical cleaning steps.

🔹 Why It Matters?

A well-programmed pallet washer follows strict hygiene protocols, ensuring that every pallet is sanitized to the same high standard.

✅ Uses Sanitization & Drying Features for Maximum Hygiene

✔ Some machines include steam or chemical disinfection options to enhance hygiene.

✔ Drying features prevent moisture buildup, reducing mold and bacterial growth.

🔹 Why It Matters?

Moisture left on pallets can promote bacterial growth, undoing the effects of washing.

🔹 Industries That Benefit from Pallet Washing Machines

Many industries require clean and sanitized pallets to prevent cross-contamination. Here’s how different sectors benefit:

🍖 Food & Beverage Industry

✅ Prevents bacterial contamination in meat, dairy, and fresh produce handling.

✅ Ensures compliance with HACCP, FDA, and ISO hygiene standards.

💊 Pharmaceutical & Healthcare Industry

✅ Removes chemical and biological contaminants from pallets used for medicines.

✅ Ensures sterile transport and storage conditions.

🏭 Manufacturing & Logistics

✅ Keeps pallets free from dirt, oil, and industrial residues.

✅ Ensures that cross-contamination between raw materials and finished products is avoided.

🛍️ Retail & Packaging

✅ Prevents allergen contamination in packaging materials and consumer goods.

✅ Ensures that products are delivered on clean, dust-free pallets.

🔹Features to Look for in a Pallet Washing Machine

When selecting a pallet washer, consider the following features to ensure maximum efficiency and hygiene:

🔸 High-Pressure Spray System – Removes tough contaminants effectively.

🔸 Adjustable Water Temperature – Hot water improves sanitization.

🔸 Detergent & Disinfection System – Ensures thorough cleaning of pallets.

🔸 Water Filtration & Recycling – Reduces water usage while maintaining cleanliness.

🔸 Fast Drying Function – Prevents bacterial growth on washed pallets.

🔸 Capacity & Throughput Speed – Choose a model that meets your daily washing volume.

🚀 Example: A food processing plant using a high-speed pallet washer with an automated drying system reduced contamination risks by 90% while cutting cleaning time in half.

🔹Best Practices for Using a Pallet Washer

To maximize the effectiveness of your pallet washing machine, follow these best practices:

✅ Establish a Regular Cleaning Schedule

🕒 Set washing cycles based on usage frequency and contamination risks.

✅ Separate Contaminated & Clean Pallets

🚛 Keep dirty pallets away from cleaned ones to avoid re-contamination.

✅ Use Proper Cleaning Agents

🧴 Choose food-safe or industry-approved detergents for effective cleaning.

✅ Monitor & Maintain the Machine Regularly

🛠️ Check spray nozzles, water filters, and heating elements to ensure optimal performance.

✅ Train Staff on Hygiene Protocols

👨🏫 Ensure employees understand the importance of pallet sanitation and follow proper handling procedures.

🔹 Conclusion: Invest in a Pallet Washing Machine for a Safer, Cleaner Operation

A pallet washing machine is a critical investment for businesses looking to prevent cross-contamination and maintain hygiene compliance. By automating the cleaning process, it ensures thorough sanitation, reduces human error, and minimizes the risk of product contamination.

At LONKIA Machinery, we offer high-efficiency pallet washers designed for food, pharmaceutical, and industrial applications. Our machines feature advanced washing, drying, and sanitization technology to keep your pallets clean and contamination-free.

🚀 Want to improve hygiene and safety in your facility? Contact us today to learn more about our pallet washing solutions!