In industries like food processing, logistics, and manufacturing, maintaining clean pallets is critical for operational efficiency, safety, and hygiene. Pallets are used extensively to transport goods, and over time, they accumulate dirt, debris, and contaminants. Cleaning them manually is labor-intensive, time-consuming, and inconsistent. That’s where a pallet washing system comes into play.

In this ultimate guide, we’ll walk you through everything you need to know to choose the best pallet washing system for your business, including the key features, types of systems available, and how to assess your specific needs.

Why Do You Need a Pallet Washing System?

Increased Hygiene Standards:

In industries like food processing, hygiene is paramount. A pallet washing system ensures that your pallets are consistently cleaned to meet health and safety regulations. Manual cleaning can lead to inconsistent results, potentially leaving behind harmful contaminants, which can affect the quality of your products.

Labor Savings:

Manual cleaning can take up significant time and workforce. By automating the process with a pallet washing system, you can free up labor for more productive tasks, ultimately improving efficiency and reducing labor costs.

Improved Productivity:

A well-functioning pallet washing system increases throughput by enabling a continuous washing cycle. It minimizes downtime compared to manual labor, helping your operations run more smoothly.

Environmental Benefits:

Modern pallet washing systems often include water recycling and filtration systems, reducing water consumption and wastewater disposal costs. This not only helps your business become more eco-friendly but also reduces operational costs.

Key Features to Look for in a Pallet Washing System

When selecting a pallet washing system, it’s essential to consider the following features to ensure that it meets your needs:

Washing Capacity

How many pallets do you need to clean daily? A high-capacity system will be required if your business handles large volumes of pallets. Look for systems that can accommodate your throughput needs without compromising performance.

Cleaning Efficiency

Does the system offer high-pressure washing? High-pressure jets effectively remove dirt and grime, ensuring thorough cleaning. Some systems also include rotating brushes for extra scrubbing power.

Water Recycling

Look for pallet washers that include water filtration and recycling systems. These systems can filter and reuse the water, significantly reducing water consumption and minimizing your business’s environmental footprint.

Durability

A pallet washing system is an investment. Ensure that the system is made from stainless steel or other durable materials to withstand the rigors of constant use and exposure to water and cleaning chemicals.

Space Efficiency

Evaluate the available space in your facility. If space is limited, opt for a compact pallet washing machine that can easily fit into your production line without disrupting operations.

Automation and Controls

Consider a system with automated features such as adjustable wash cycles, temperature controls, and water pressure settings. These features can improve the flexibility and performance of the system.

Types of Pallet Washing Systems

There are several different types of pallet washing systems available, and choosing the right one depends on your specific needs.

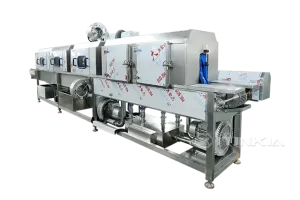

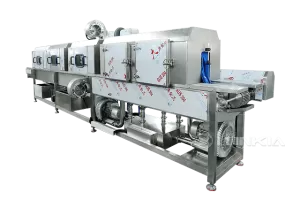

Conveyorized Pallet Washing System

Best for high-volume operations.

Pallets move through a conveyor belt system, passing through washing and rinsing stages. This type of system is ideal for businesses that require continuous cleaning with minimal manual intervention.

Batch Pallet Washing System

Best for lower-volume operations.

Pallets are washed in batches, making this system a more cost-effective solution for smaller businesses or those with less frequent pallet cleaning needs. Batch systems are usually more compact and affordable.

Mobile Pallet Washing System

Best for flexibility.

These systems are typically smaller and can be moved between various areas of your facility. They are an excellent choice for businesses that need to clean pallets in multiple locations or that have variable pallet cleaning needs.

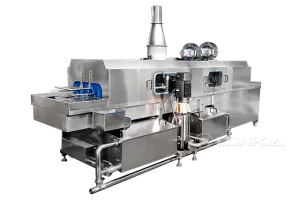

Automated Pallet Washer

Best for hands-free operation.

Fully automated pallet washers offer complete automation, from loading to cleaning and unloading. This system is highly efficient and minimizes human involvement, making it perfect for businesses looking for maximum productivity.

How to Assess Your Needs and Choose the Right System

Choosing the best pallet washing system requires a deep understanding of your business’s operations and requirements. Here are some questions to help guide your decision-making process:

What is Your Pallet Volume?

Estimate how many pallets you need to clean per day. For high-volume operations, an automated or conveyorized system may be best, while lower volumes may suit a batch or mobile system.

What Are Your Space Constraints?

Evaluate your available space in the facility. If space is limited, consider a more compact system. Some manufacturers offer modular systems that can be scaled as your business grows.

What Are Your Environmental Goals?

If reducing water consumption is a priority, look for systems with water recycling capabilities. This feature is especially important for businesses operating in areas with water scarcity or those aiming to lower their environmental impact.

What is Your Budget?

Determine how much you are willing to invest. While automated and conveyorized systems can be costly, they often provide greater efficiency, which can translate into cost savings in the long run. Batch or mobile systems may have a lower upfront cost but could require more labor to operate.

Maintenance and Service Considerations

To keep your pallet washing system running smoothly, regular maintenance is essential. Look for a system that:

- Is easy to clean and maintain.

- Offers service agreements or warranty packages.

- Has readily available spare parts and technical support.

Routine checks and cleaning will extend the lifespan of your pallet washing machine, ensuring that it continues to operate efficiently over time.

Conclusion: Investing in the Right Pallet Washing System

Investing in a pallet washing system is an important step toward improving your business’s operational efficiency, productivity, and hygiene standards. Whether you are in the food industry, manufacturing, or logistics, a high-quality pallet washer can help you reduce labor costs, improve cleaning consistency, and create a safer, more productive working environment.

At LONKIA Machinery, we provide a range of pallet washing systems tailored to meet your specific needs. From high-volume conveyorized systems to compact mobile washers, we offer durable and efficient solutions to help your business thrive.

Contact us today to learn more about our pallet washing systems and how they can streamline your operations while reducing costs.