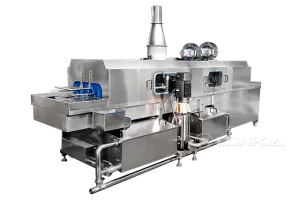

In modern food processing and agricultural production, bubble washing machines are increasingly attracting attention and use due to their high efficiency and environmental protection. As a leading equipment manufacturer in the industry, LONKIA will introduce the working principle of the bubble washing machine and its main application areas in detail.

Working principle of bubble washing machine

The working principle of the bubble washing machine is mainly to use the equipment in the front part of the box to inject an appropriate amount of water into the box, and heat the water temperature through the heating pipe. When the raw materials pass through the box, they will roll under the joint action of the bubble machine and water, and continue to move forward with the mesh belt. At the same time, the equipment uses high-pressure water flow and bubble generating devices to impact the surface of the object to be cleaned. The energy generated by the bursting of bubbles when in contact with the object will have an impact and scrub effect on the surface of the object, thereby cleaning the surface of the object.

In addition, the high-pressure water flow makes the material roll, which can effectively remove agricultural residues, mud and dust on the surface of the product. The floating objects in the vegetable washing machine can overflow from the overflow tank, and the sediment is discharged from the sewage outlet. Some bubble washing machines are also equipped with brushes, which can further effectively remove hair from the items.

How does the bubble washer work?

- Material transportation Firstly, the materials to be cleaned enter the cleaning tank through a conveyor belt or manual method.

- Bubble generation Seconedly, the bubble generator injects air into the water to generate a large number of bubbles, forming a strong water flow and bubble flow.

- Bubble cleaning Nextly, the bubbles come into contact with the materials during the rising process, and the impact force generated when the bubbles burst removes the dirt, impurities and microorganisms on the surface of the materials.

- Circulation filtration The sewage after cleaning is circulated through the filtration system to ensure the cleanliness of the cleaning water and reduce the waste of water resources.

- Material discharge Last, the cleaned materials are discharged through a conveyor belt or other means and enter the next processing link.

This working principle gives the bubble cleaning machine many advantages. It not only saves water, electricity and time, but also is clean and hygienic; it will not damage vegetables and other materials during the cleaning process, has high efficiency, occupies a small area, is safe and reliable; it is simple to install, easy to operate, easy to maintain, and has low energy consumption. The cleanliness of the cleaned objects is more than three times higher than that of the conventional manual washing method.

What fields is the bubble washer mainly used for?

Bubble washing machines have a wide range of applications, mainly including the following aspects:

- Fruit and vegetable washing Bubbling washing machines are widely used in the washing of various fruits and vegetables, such as apples, pears, grapes, spinach, cabbage, etc. It can effectively remove mud and pesticide residues on the surface of fruits and vegetables to ensure food safety and hygiene.

- Aquatic product washing In aquatic product processing, bubble washing machines are used to wash seafood such as fish, shellfish, shrimp, etc. Through bubble washing, mud, parasites and other impurities on the surface of aquatic products can be removed to improve product quality.

- Chinese herbal medicine cleaning Chinese herbal medicines will carry a lot of dirt and impurities during the harvesting and processing process. Bubble cleaning machines can efficiently clean various Chinese herbal medicines to ensure their purity and efficacy.

- Meat processing In the meat processing industry, bubble washing machines are used to wash various poultry and livestock meats, remove blood stains, hair and other impurities on the surface, and improve the hygiene standards of meat products.

- Food processing During food processing, bubble washers are used to clean various raw materials, such as beans, grains, etc., to ensure the quality and safety of processed foods.

In short, LONKIA's bubble washers, with their unique working principle and wide range of applications, have brought efficient and convenient cleaning solutions to the food processing and agricultural product processing industries. Whether in clean vegetable processing plants, large food distribution centers, or kitchens and other places, bubble washers can play an important role, helping users improve production efficiency, ensure product quality, and meet people's needs for healthy and safe food. If interested, please contact us at any time.