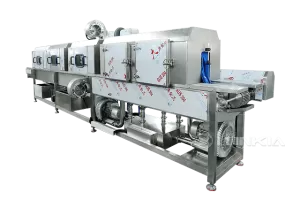

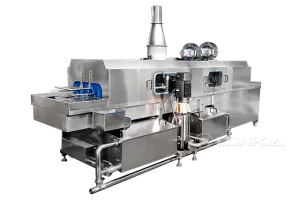

Maintaining food safety standards in the food industry is crucial, and one often overlooked aspect of this is the cleanliness of pallets used to transport goods. Pallets can harbor dirt, bacteria, and other contaminants that may compromise food safety. This is where an automated pallet washer becomes an essential part of the process.

Consistent and Reliable Cleaning

Automated pallet washers provide consistent cleaning every time, ensuring that all pallets are thoroughly washed to meet hygiene standards. Manual cleaning can be inconsistent, potentially leaving behind harmful bacteria or residues that could contaminate food products. With automation, the system ensures the right amount of water pressure, detergent, and wash time, significantly reducing the risk of contamination.

Compliance with Health and Safety Regulations

Food safety regulations require that pallets used in the food industry are kept clean to avoid contamination. An automated pallet washer helps businesses stay compliant with these regulations by ensuring that pallets are cleaned to the highest standards. The system's ability to recycle water and maintain consistent wash cycles further supports compliance with environmental and water conservation guidelines.

Efficiency and Labor Cost Savings

Manual pallet washing is labor-intensive and prone to human error. By automating the process, businesses can reduce the number of labor hours required for cleaning while improving the overall efficiency of the operation. The automated system works faster, freeing up workers to focus on other tasks, and reducing the cost of labor over time.

Enhanced Hygiene and Reduced Cross-Contamination

Automated pallet washers are designed to remove contaminants, oils, grease, and dirt that may otherwise be missed during manual cleaning. This reduces the risk of cross-contamination between pallets and ensures that food safety standards are upheld throughout the supply chain. Cleaner pallets mean safer food products for consumers.

In conclusion, an automated pallet washer is an essential investment for businesses in the food industry. It ensures consistent cleanliness, compliance with food safety standards, and helps improve efficiency, all while reducing the risk of contamination. With automation, businesses can focus on maintaining high hygiene levels without sacrificing productivity or cost-effectiveness.