In industries such as food processing, pharmaceuticals, logistics, and manufacturing, maintaining clean and sanitized pallets is essential for hygiene, regulatory compliance, and operational efficiency. However, manual pallet washing is labor-intensive, time-consuming, and inconsistent, leading to higher costs and potential contamination risks.

Investing in an automated pallet washer can streamline cleaning operations, reduce costs, and improve hygiene standards. This article explores why an automated pallet washer is a smart investment for your facility and how it can enhance productivity, cost savings, and compliance.

🔹 Enhanced Cleaning Efficiency and Speed

✅ The Challenge:

Manual washing is slow and inconsistent, leading to bottlenecks in production. High-volume facilities struggle to keep up with cleaning demands, causing delays and hygiene risks.

🔧 How an Automated Pallet Washer Solves This:

✔ Processes hundreds of pallets per hour, reducing downtime.

✔ High-pressure water jets ensure thorough cleaning in less time.

✔ Consistent washing cycles provide uniform cleanliness across all pallets.

🔹 Example:

An automated pallet washer can clean up to 500 pallets per hour, compared to manual washing, which may only handle 30-50 pallets per hour.

🔹 Significant Labor Cost Reduction

✅ The Challenge:

Manual pallet cleaning requires multiple workers, increasing labor expenses and leading to inconsistencies in cleanliness.

🔧 How an Automated Pallet Washer Solves This:

✔ Reduces the number of workers needed for pallet washing.

✔ Automated conveyor systems transport pallets through cleaning stages without manual handling.

✔ Less physical labor means fewer work-related injuries and lower absenteeism.

🔹 Example:

A facility switching to automation can cut labor costs by up to 60%, reallocating workers to higher-value tasks.

🔹 Improved Hygiene and Regulatory Compliance

✅ The Challenge:

In industries like food processing and pharmaceuticals, poorly cleaned pallets can lead to cross-contamination, product recalls, and regulatory violations.

🔧 How an Automated Pallet Washer Solves This:

✔ High-temperature sanitization (above 85°C) kills bacteria and pathogens.

✔ Consistent detergent dosing eliminates residue and contaminants.

✔ Meets industry hygiene regulations (HACCP, FDA, GMP, ISO 22000).

🔹 Example:

Many food and pharmaceutical companies must meet strict hygiene standards—automated pallet washers ensure full compliance with sanitation protocols.

🔹 Water and Energy Conservation

✅ The Challenge:

Manual washing wastes large amounts of water and energy, increasing operational costs.

🔧 How an Automated Pallet Washer Solves This:

✔ Water recycling systems reduce consumption by up to 50-80%.

✔ Energy-efficient heating minimizes power usage.

✔ Smart sensors adjust water flow based on contamination levels, preventing waste.

🔹 Example:

A water filtration system in an automated washer can cut water usage by half, saving thousands in annual operating costs.

🔹 Extended Pallet Lifespan

✅ The Challenge:

Harsh manual scrubbing and inconsistent washing can damage plastic and wooden pallets, reducing their lifespan.

🔧 How an Automated Pallet Washer Solves This:

✔ Gentle, high-efficiency spray nozzles prevent wear and tear.

✔ Precise temperature control avoids material warping.

✔ Consistent detergent application prevents pallet degradation.

🔹 Example:

Proper cleaning with an automated system can extend pallet lifespan by 30-50%, reducing replacement costs.

🔹 Scalability for Growing Businesses

✅ The Challenge:

As businesses scale up, manual pallet washing becomes inefficient and unsustainable.

🔧 How an Automated Pallet Washer Solves This:

✔ Modular designs allow facilities to increase washing capacity as demand grows.

✔ Fully integrated conveyor systems automate large-scale cleaning operations.

✔ Customizable wash settings accommodate different pallet types and contamination levels.

🔹 Example:

A business processing 500+ pallets per day benefits from an automated system that keeps pace with demand without adding extra labor costs.

🔹 Faster ROI and Long-Term Cost Savings

✅ The Challenge:

Some businesses hesitate to invest in automation due to the initial cost. However, long-term savings on labor, water, and detergent costs make automation a smart financial decision.

🔧 How an Automated Pallet Washer Solves This:

✔ Lower labor and resource costs improve profitability.

✔ Higher production efficiency reduces downtime.

✔ Sustainable resource use leads to long-term operational savings.

🔹 Example:

Companies that invest in automated pallet washers often recoup their investment within 1-2 years due to significant labor and utility savings.

🔹 Conclusion: A Smart Investment for Modern Facilities

Investing in an automated pallet washer offers significant benefits for efficiency, cost savings, and hygiene compliance.

Key Advantages of Automation:

✅ Faster and more efficient cleaning

✅ Lower labor costs and fewer workplace injuries

✅ Improved hygiene and compliance with regulations

✅ Water and energy conservation for sustainability

✅ Extended pallet lifespan and reduced replacement costs

✅ Scalability to match business growth

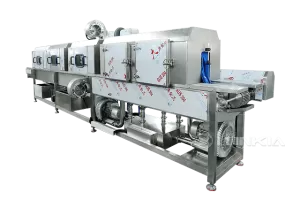

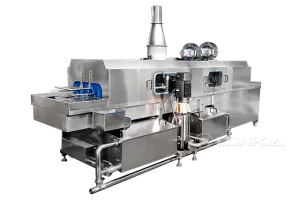

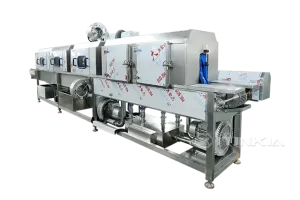

At LONKIA Machinery, we offer high-performance automated pallet washers tailored to the needs of food, logistics, and industrial processing facilities. Contact us today to learn how our automated cleaning solutions can optimize your operations, cut costs, and improve hygiene compliance! 🚀