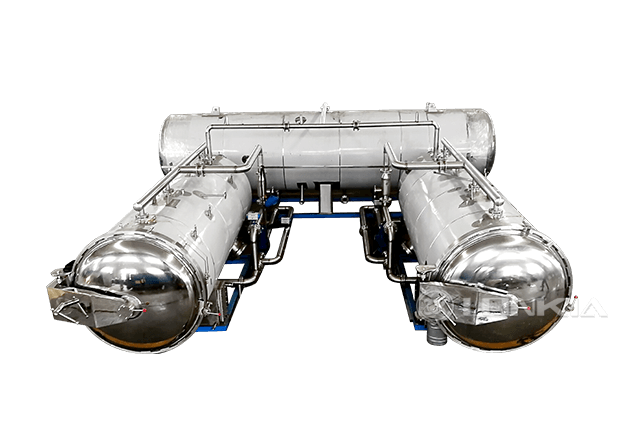

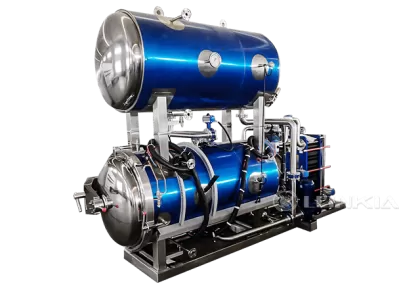

Even Heating

The rotary retort is designed with rotation to evenly distribute the heating medium on the surface of the food, achieving uniform heating and sterilization.

Efficient Sterilization

The rotary retort can complete the sterilization process of a large quantity of food in a short period, thus improving production efficiency.

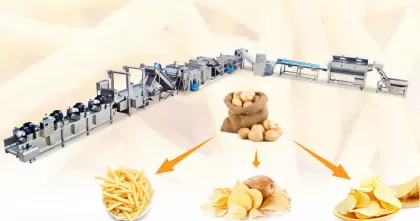

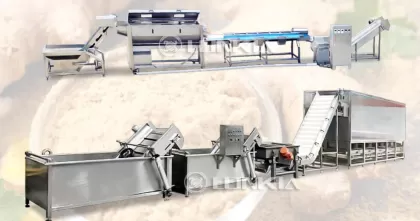

Suitable for Various Products

It is capable of sterilizing various types of food, including canned, bagged, and bottled food items.

Reliable and Stable Operation

With superior performance, it can operate reliably and stably for extended periods with low failure rates, ensuring food quality.

Email:

[email protected]