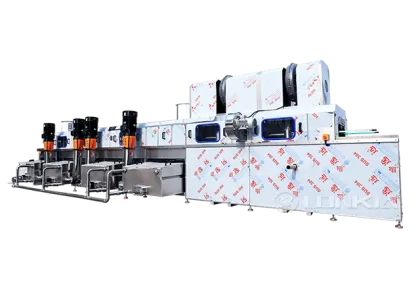

The design of the Automatic Crate Washing Stacking Production Line fully considers precision and efficiency, integrating key components such as a high-performance crate washer and a robot palletizer. From thoroughly removing dirt and contaminants to safely stacking the crates, every element works in harmony to deliver optimal results. Our advanced control system allows for real-time monitoring and management of the entire process, ensuring seamless operation. This comprehensive solution enables food processing facilities to streamline their operations while maintaining uncompromising standards of cleanliness and efficiency, ultimately fostering sustained business growth.

The Automatic Crate Washing Stacking Line ensures optimal hygiene and efficiency through a streamlined cleaning process. The crates first go through a pre-cleaning stage to remove loose debris, followed by a high-pressure wash through the crate washer, which utilizes advanced water jet technology and detergents to thoroughly remove dirt and contaminants. After a thorough rinsing to remove any residual detergent, the cleaned crates are automatically arranged in a stable configuration during the stacking phase, ready for storage or transportation.