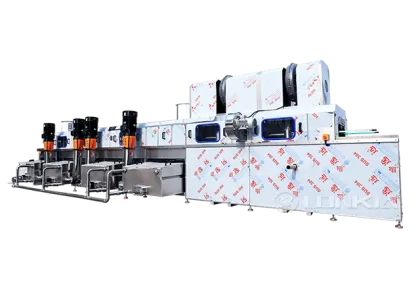

Lonkia chicken crate washing machine is an integrated and efficient system that covers the pre-treatment, cleaning, disinfection and stacking of chicken cages. First of all, the cages are transported to the soaking area through the intelligent manipulator or conveyor belt system, where they are fully soaked with a special cleaning solution to soften the feces, grease and other stains adhering to the surface of the cages.

Subsequently, the chicken crate enters the high-pressure cleaning area. The basket washer passes through using high-pressure water flow to thoroughly rinse off the residual dirt, ensuring that the cleaning effect meets industry standards. After cleaning, the cages will automatically enter the disinfection area of chicken crate washing machine for comprehensive sterilization treatment, effectively reducing the risk of bacterial transmission. The final stage of the washing line is the automatic stacking system, which neatly stacks the cages for subsequent transportation and storage.

This highly automated chicken cage cleaning and stacking production line not only greatly improves work efficiency, but also significantly reduces errors and heavy labor intensity in manual operation, significantly improving the production efficiency of the farm. If you wish to achieve a hygienic and efficient production environment and reduce operating costs, please feel free to contact us for customized solutions.