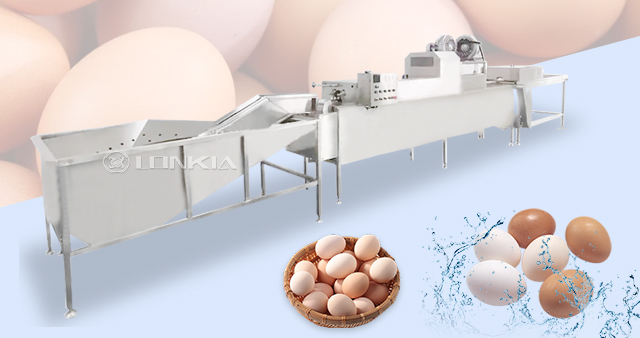

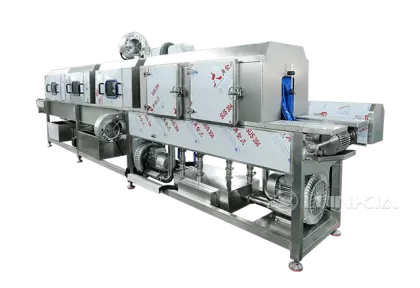

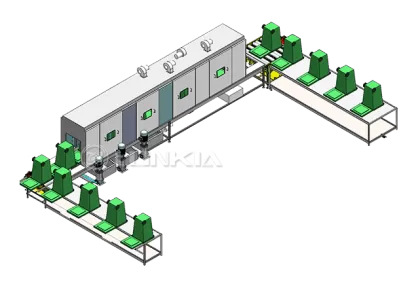

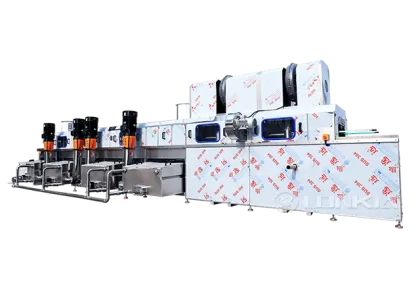

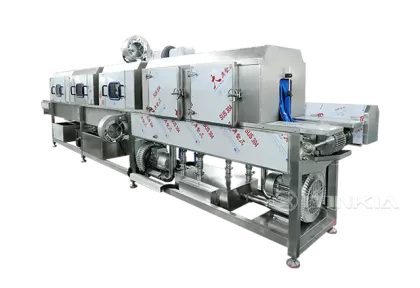

Egg washing line mainly includes several automatic links, each link has specialized equipment to complete specific functions. First, the eggs enter the egg washing tank, where the water rinses to remove surface dust and stains. The cleaning roller further scrubs the shells with soft bristles to ensure deep cleaning.

After cleaning, the eggs pass through a light inspection process, which detects cracks and abnormalities and rejects substandard products. Eggs that meet the standards then go through an automatic inkjet printer, which identifies the date of production or brand information to enhance product traceability.

To ensure food safety, the eggs undergo ultraviolet sterilization before packaging to effectively kill bacteria and viruses and extend the shelf life of the eggs. Finally, the eggs are sorted and packaged through the egg collection and transportation system to ensure the safety and efficiency of the eggs in circulation.

The automated process of the egg washing line effectively improves the cleaning effect and production efficiency, reduces labor costs, and ensures the quality and safety of the final product, making it an indispensable piece of equipment for the egg processing industry.