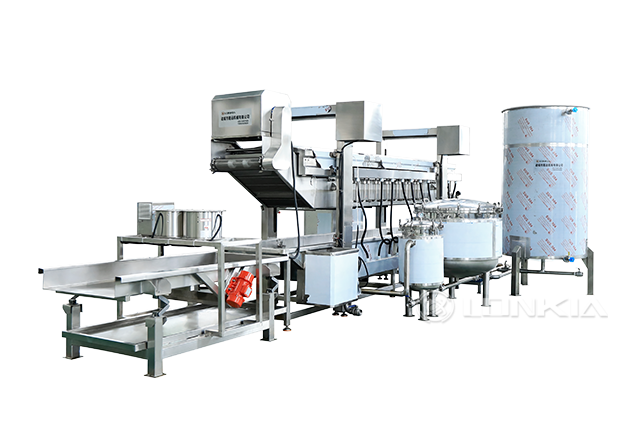

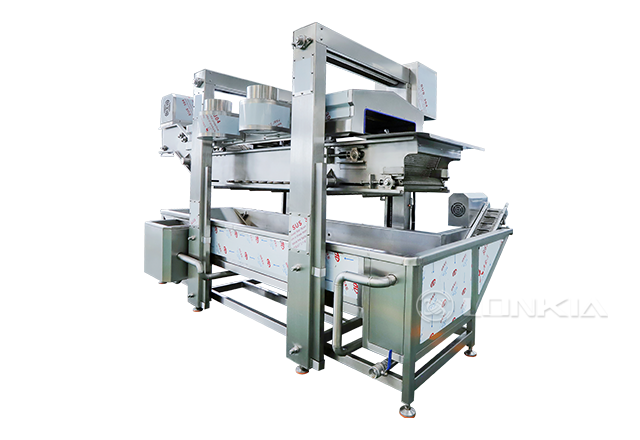

The Garlic Peeling Processing Line utilizes pneumatic principles to process crushed garlic into undamaged cloves, eliminating the need for soaking in water. It is suitable for most garlic varieties, achieving a peeling rate of over 95%. Additionally, the line can be integrated with corresponding equipment to produce garlic paste, garlic slices, garlic powder, and more, meeting various production needs.

Lonkia Garlic Peeling Processing Line uses the pneumatic principle to peel up to 3,000 kilograms of garlic per hour for efficient peeling. Pneumatic peeling technology avoids mechanical damage and ensures that the garlic cloves remain intact, preserving the best flavor. Modular design and removable parts are easy to clean and meet strict hygiene standards. The equipment is flexible to adapt to various garlic varieties and sizes and can be customized to meet different customer needs, please contact us immediately if you need.