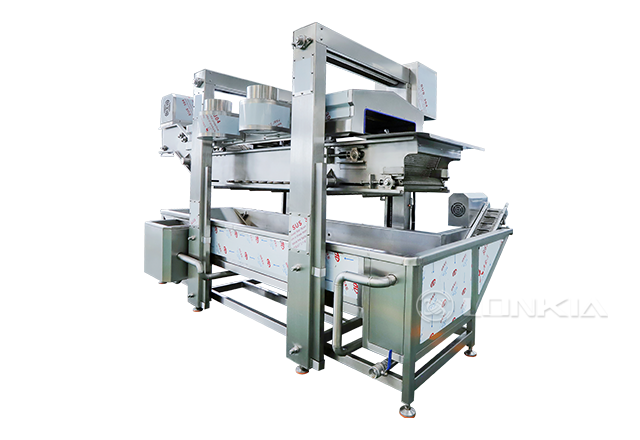

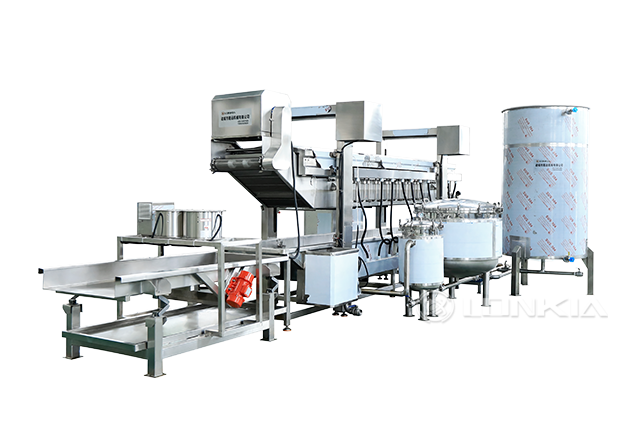

The potato cutting and washing line combines a variety of advanced equipment to achieve an efficient cutting and cleaning process. Firstly, the potatoes are soaked and then conveyed into the brush rolling peeler to remove the soil and impurities from the surface of the vegetable, so as to prepare for the subsequent processing. Afterwards, the potatoes are fed into a vegetable cutter, which cuts the vegetables into julienne or diced pieces as needed. Finally, the vortex vegetable washing machine deep-cleans the diced or shredded potatoes after cutting to ensure that the product meets hygiene standards.

The high flexibility of this potato processing line enables it to process a wide range of vegetables according to the needs of different customers, so it is widely used in food processing plants, catering and supermarket vegetable processing departments. Due to the high degree of automation, easy operation, and the design of the equipment in line with food hygiene standards, it can greatly improve production efficiency, reduce labor costs, and ensure that the processed vegetables are of high quality.