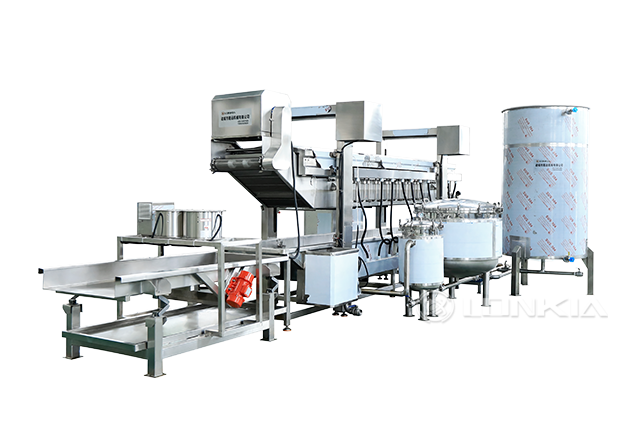

The potato washing and blanching line is a complete potato processing line designed to improve automation and product quality in the production of potato strips. The line consists of a number of high-performance equipment, including soaking elevators, high-end brush rolls, vegetable cutters, bubble washers, blanching machines, etc. Each step of the process is strictly controlled to ensure the quality and taste of the potato fries.

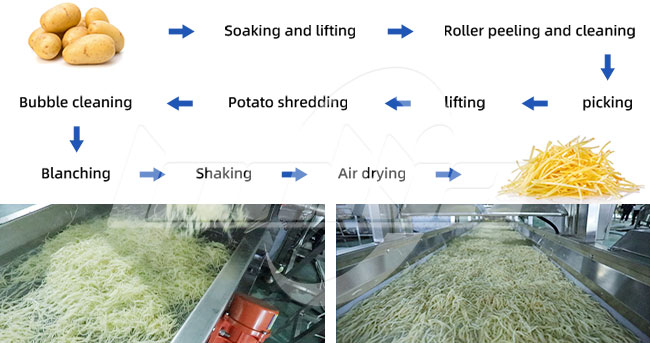

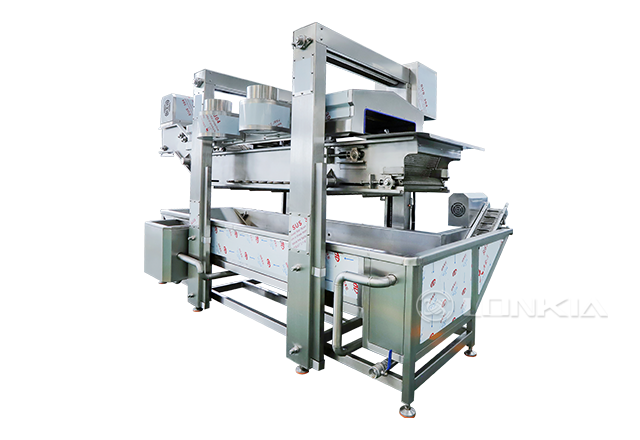

The workflow of the potato processing line is simple and efficient. First, the potatoes enter the cleaning stage through the soaking elevator, utilizing the brush roll to remove surface soil and impurities. Next, the vegetable cutter cuts the potatoes into uniform strips, and then the potato strips are fed into the bubble washing machine, which cleans the surface and removes excess impurities through the bubbling water stream. Finally, the potato strips are treated by hot water rinsing in the blanching machine to further ensure the color and taste of the potato strips.

The whole production line adopts automatic control system and is easy to operate. Not only can it effectively improve the production efficiency and reduce the labor cost, but also its stable and advanced processing effect can meet the market demand for high-quality potato sticks.