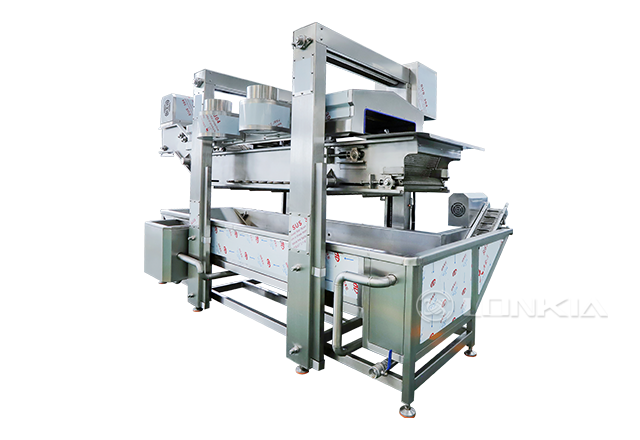

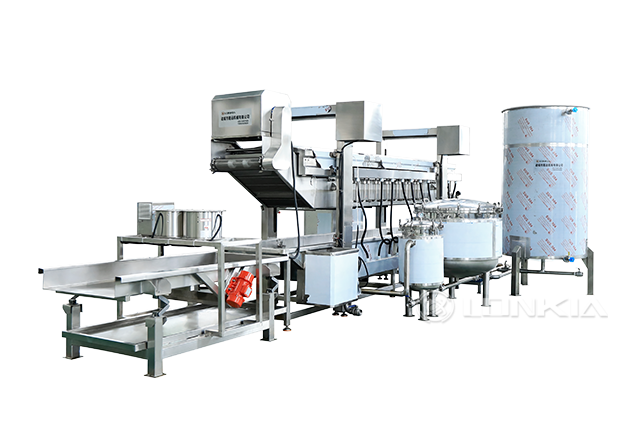

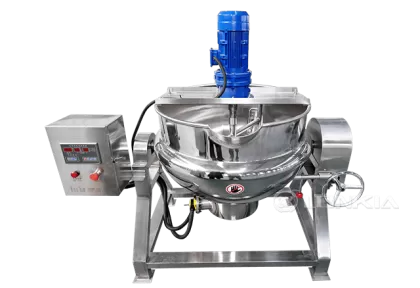

The salad processing line adopts advanced automated equipment and strictly follows the hygienic standards of food processing. The whole production line consists of several key equipments, including inspection and conveying table, vegetable cutting machine, soaking machine, vortex washing machine, automatic dehydrator, etc., which ensures the efficient processing of vegetables from raw materials to finished products.

Fresh vegetables first pass through an inspection conveyor to remove poor quality ones, then enter the vegetable cutting machine to be sliced, shredded, or diced. Next, the vegetables are soaked for pre-treatment to remove impurities and pesticide residues, preserving their crispness. Afterward, they are cleaned in a vortex washing machine using high-pressure water and air bubbles. The vegetables then go through a fully automatic spin dryer to remove surface moisture, ensuring freshness and taste. Eventually, the dehydrated vegetables can be directly used for packaging and cold chain distribution of ready-to-eat salads, meeting the market demand for healthy and convenient food.

The entire salad production line has a compact design, small footprint, easy maintenance and operation, and realizes highly efficient automated operation. It reduces manual intervention, improves production efficiency and ensures product quality, making it an ideal solution for modern salad processing.