How Does Production Capacity Affect the Price of Frozen Potato Production Line?

Frozen potato production line is a set of automated processing equipment integrating cleaning, peeling, cutting, blanching, cooling, deep-frying, degreasing, freezing and packaging. For food enterprises that want to put into production frozen French fries, the choice of capacity is directly related to the configuration and price of the entire production line. This article will focus on this core issue, analyze the direct correlation between capacity and price, to help enterprises make more reasonable…

Learn MoreHow the Frozen Potato Production Line Works: Step-by-Step Guide

The frozen potato production line is a highly automated food processing system that transforms fresh potatoes into tasty fries or chips through a series of precise steps. Lonkia frozen potato production line not only improves production efficiency, but also ensures the quality and taste of the product. In this article, we will explain in detail how each step of the process works, from washing to freezing.

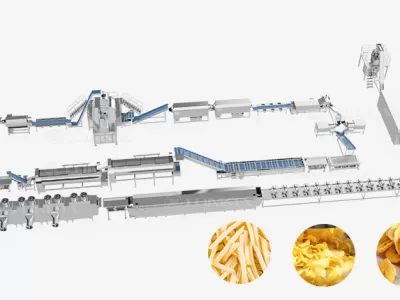

Learn MoreFrozen French Fries Production Line

The Frozen French Fries Production Line is a state-of-the-art system designed to process up to 5,000 kg of potatoes per hour, ensuring high-quality, crispy fries. This fully automated line encompasses washing, peeling, slicing, blanching, frying, and freezing stages. Utilizing Individual Quick Freezing (IQF) technology, it locks in flavor and texture, with freezing times reduced to approximately 3-5 minutes, depending on the cut thickness, maintaining the fries' nutritional value and freshness.

Learn More