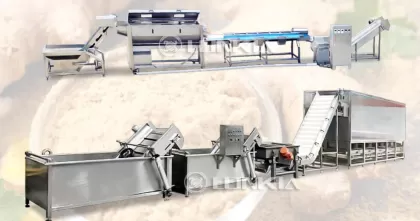

Energy-saving and Cost Reduction

It operates more efficiently than traditional peeling equipment. By altering the steam supply method, it conserves energy and reduces production costs.

Hygiene and Safety

It kills bacteria on the surface of fruits and vegetables during the peeling process, preventing food cross-contamination and ensuring food hygiene and safety.

Reduced Food Wastage

By precisely controlling the peeling process, it reduces fruit and vegetable wastage, thereby improving the utilization of raw materials.

Suitable for Various Vegetables

By adjusting appropriate parameters to adapt to the characteristics and processing requirements of different vegetables, it can peel a variety of vegetables.

Email:

[email protected]